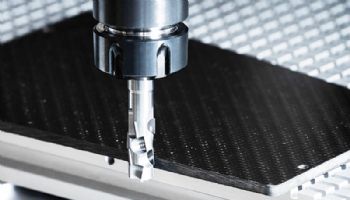

The range of cutting tools available from Birmingham-based Guhring Ltd for the machining of composite materials has been extended, with the latest additions included in a new brochure: High-performance tools for machining modern composite materials.

This 24-page publication includes the latest solid-carbide and PCD drills and end mills, taps, slot drills and PCD ‘compression’ milling cutters.

With CFRP, GFRP and multi-layered FRP materials increasingly being used in a broad range of industrial applications, Guhring has developed its product offering to meet the ever evolving needs of the market, including the aerospace, automotive, power generation marine, medical, sport and sub-contract sectors.

The new publication features new and extended product ranges that include solid-carbide stub drills and Kevlar drills from 2.5 to 10mm in diameter, the CR100- and FR100-geometry CFRP and GFRP end mills, ISO (metric) machine taps, and 90 and 120deg multi-regrindable PCD drills. Additional products include PCD slot drills with two, three and four cutting edges, and end mills with through-coolant capability.

The new tooling solutions are available with a wide variety of shank forms and tolerances, surface finishes and coatings, helix and rake angles and cutting edges.

Diamond coating is a key feature for optimising performance when cutting FRP; Guhring’s diamond coating — called Cristal — is applied in-house to ensure optimised cutting performance and consistency, as well as tool longevity.

The challenges of developing cutting tools for the composite industry lies in meeting the specific machining conditions that can occur when machining FRP materials, such as the fraying of fibres, delaminating, burrs and thermal damage.

Guhring has invested significantly in R&D to overcome these and associated difficulties.

The brochure can be found at the Web site (

www.guhring.co.uk/catalogue-downloads).