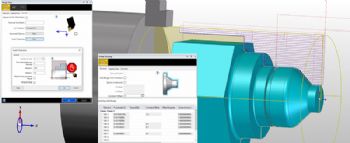

Tool-path associativity in the ‘Face Mill’ cycle, extending the ‘Parallel Lace’ tool-path, and enhanced ‘Additive undercutting’ feature in around 30 updates in the latest release of Edgecam (

www.edgecam.com) from Hexagon’s Manufacturing Intelligence division.

Alongside the new Edgecam 2020.1, the optional ‘CAD for CAM Designer’ module has now replaced ‘Part Modeler’.

More than 50 enhancements have been made to Designer, the three main ones being: the ability to attach finishing and tolerance information to models and faces with thenew ‘Surface Attributes’ command; a new ‘Edit Boundary’ command for modifying the trimming of faces directly on a sheet or solid body without having to extract any surfaces or edges; and a ‘new look and feel’ for the ‘Auto-constrained’ surface command for quickly creating complex surfaces.

Also enhanced is the ‘Additive Lace’ cycle’s ‘Undercut’ function, by allowing the user to set a maximum overhang angle, because different materials and processes require different negative material build-up (depending on the target shape).

Furthermore, the ‘Chamfering’ cycle offers five new functions (similar to those already found in the ‘Profiling’ cycle); these include greater tool-path control via the new ‘Cut Increment’ and ‘Z Offset’ modifiers, and six ‘corner strategies’ have been added to allow programmers to choose which type of external corner condition the cycle will

produce.

Product manager John Buehler said: “Tool-path associativity is a vital factor when programming production components, as CAD modifications can take considerable time.

"The latest software removes such delays by making the Face Mill cycle sensitive to the stock model. When either the stock or component solid model are altered, the tool-path automatically adjusts both the X-Y and the Z height of the tool-path.

"The tool-path in the Parallel Lace cycle can now be extended, with the extensions following the direction of the cut and applied in the primary direction, thereby ‘stretching’ the tool-path and guaranteeing better surface texture, while allowing the cycle to cater for over-size stock.”

Furthermore, an enhancement to the existing ‘Swarf’ control command means that a specific time period (in minutes) can be set for the turning insert to be in contact with the material, while ‘Tombstone Manager’ introduces a facility for production engineers working with multiple batch quantities.

‘By Tool then by Plane’ rationalises by tool, followed by reducing indexes, while ‘By Plane then by Tool’ rationalises by Plane/Datum before reducing tool changes. Edgecam 2020.1 also fully supports turrets with half positions. Mr Buehler says this can be particularly important when neighbouring tools get close to the stock and part.