Nothing but rotational plastic components are machined in batches from 30 to 20,000 at the Hertfordshire factory of sub-contractor Plastic Turned Parts (PTP), which in the four years to the end of 2019 invested more than £750,000 in six new CNC turning centres and doubled its turnover.

Five of these machines were from Citizen Machinery — four Cincom sliding-head lathes and (most recently) a Miyano fixed-head model — bringing the total number of lathes on-site from this supplier to nine.

Three turn-mill centres of different makes are used for machining bar and billets up to 65mm and 150mm in diameter respectively, and a Haas CNC mill has been in use since 2005 for occasional second-operation work where appropriate.

All except two of the Citizen lathes are fitted with PTP’s default option — bar magazines from Italian manufacturer Iemca, which is represented in the UK and Ireland by the Salisbury-based sales and service agent 1st Machine Tool Accessories Ltd (1st MTA —

www.1mta.com).

A fixed-head Miyano on site for chuck work has no bar feed, and there is one 16mm-capacity Cincom ‘slider’ with another make of bar magazine; PTP’s managing director and owner, Jonathan Newis, says he wishes he had not acquired this one, as it is temperamental.

He said: “To enable us to achieve sustained business growth, we only use the best production equipment on the market.

“That applies to everything in use on the shopfloor, including the bar feeds, which is why there are seven Iemcas in use here.

“We particularly like the Elite model fitted to our smallest-capacity 12mm sliding-head lathe, which has a big-bore kit to allow it

to take 16mm-diameter bar.

“The magazine can be swapped over in a matter of seconds from gravity bar feed to walking-beam operation for reliably advancing stock less than 6mm in diameter.”

Also singled out for praise is an Iemca Boss 338-HD Superfast feeding a 20mm-capacity slider.

“Turning flexible plastic bar is an ‘esoteric art’, one of the problems being that — unlike metal bars — thinner stock sags under

its own weight, both within the magazine and in the space between it and the lathe.

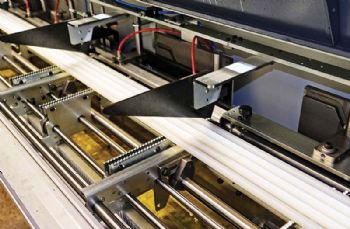

“Through 1st MTA, the Italian manufacturer modified the bar feed to include solid panels rather than standard cross struts to support the plastic bars along the length of the magazine.

“Also included were bespoke clamping blocks to ensure that small-diameter bar remains horizontal in the gap between the bar feed and the turning centre.”

Turning modes

Furthermore, there are three standard programs in the Siemens touch-screen control fitted to the Iemca Boss that can be called up according to the mode of lathe operation, whether it is standard Swiss-type turn-milling, guide bush-less machining, or turning thinner bar with the clamping blocks in use.

Mr Newis added: “We have been using Iemca bar magazines since we took over a turned parts sub-contractor on this site and inherited two Cincom sliding-head lathes and three cam-type autos.

“We bought our first new Citizen slider in 2007 — a 16mm-capacity machine — to replace the cam machines.

“In all that time, the bar feeds have proved to be reliable and well built, which translates into absence of vibration and hence high dimensional accuracy of machined components — and good surface finishes.”

The original lathe from 2007 (still in use today) is fitted with a Genius 118-37 which, like all Iemca bar feeds, has a double bar pusher to reduce the overall length of the magazine and save factory space.

Another bar feed in use is a Smart 320 (on a second 16mm slider) featuring snap-in guide channels for rapid bar change-over and a self-centring bush at the front to guide the bar.

There is also a KID short magazine feeding 1m bar into a 51mm-capacity Miyano fixed-head lathe.

This unit takes less space than the 3m bar magazines on site, while the absence of a gripper means that the remnant is small (it is easily pushed out of the front and ejected, avoiding the job of extracting remnants from the back of a full-length magazine and so maximising spindle up-time).

Chip control

The four latest Citizen machines to be installed at PTP feature the Japanese manufacturer’s LFV (low-frequency vibration) two-axis oscillating chip-breaking software; this is especially helpful when turning plastics, many of which tend to produce ‘bird nests’ of long stringy swarf.

The main ‘culprits’ are polyethylenes and thermoplastics, although fluoropolymers also have a tendency to string.

Mr Newis said: “With either of the two LFV software modes switched on when turning these materials, swarf is broken into short lengths that do not wrap around the component or spindle.

“We can even program the ideal length of swarf through P1 and P2 codes that set the frequency of oscillation, so that unnecessarily small plastic chips do not build up and clog the machine.

“This level of swarf control results in higher productivity and lower labour costs, as we no longer have to include regular breaks in programs — typically hourly — to stop the lathes for swarf to be cleared from the working area. ‘Lights out’ running also becomes possible, leading to higher profitability and allowing us to quote more-competitive prices and win extra business.

“Associated difficulties — such as stringy swarf rubbing against the component and generating heat that can melt the plastic — are similarly avoided, as is scrap resulting from broken drills and misalignment when picking up a part in the sub-spindle during parting-off.”

With regard to tooling, Mr Newis says inserted carbide tools are mainly used, with the sharpest varieties designed for machining aluminium preferred.

“That said, single-point turning tools can leave burrs and sometimes result in poor surface finish, especially when machining grooves, chamfers, radii and thread ends, so form tools are frequently used for turning such features.

“Another trick of the trade when using LFV is to flatten the flank relief angle of the insert so the tool recuts the material, simulating

a wiper effect for producing a superior surface finish.”

The combination of Iemca bar magazines feeding Citizen lathes, coupled with the sub-contractor’s specialism and long experience turn-milling only plastics to within ±50µm — and sometimes ‘tighter’ — continues to underpin PTP’s success.

This is despite the materials’ difficult-to-predict behaviour on ‘normalisation’ after machining, which can cause expansion or contraction.

In addition to working for OEMs, the company regularly receives jobs from metal-working sub-contractors that do not have the experience or patience to machine plastics, especially to tight tolerance.