The latest release of WorkNC (2020.1), from Hexagon’s Production Software portfolio, is said to make ‘smart factories even smarter’ with new and enhanced functions that address a number of manufacturing issues.

Walter Neveux, WorkNC ‘product owner’, says developers have looked at several production questions.

For example, how many rest-roughing processes do you apply, and how lengthy are they? How much stock material do you leave for pre-finishing and finishing, and could it be less? Also, could pre-finishing be eliminated altogether?

He says that when machining with high-feed cutters but calculating with a theoretical circular insert, the resulting stock left will be inherently uneven.

“WorkNC 2020.1’s Roughing with Advanced Toolform technology allows the milling process to deliver a more-accurate roughing stock, eliminating imprecisions characteristic of the traditional parametric tool-path calculation; and while the main roughing cycle takes the same time to machine as previously, the more-precise result allows all subsequent rest-roughing tool-paths to be significantly faster in both calculation and machining times.

Tests have shown improvements in the rest-roughing area of up to 70%.”

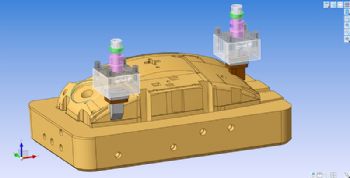

WorkNC Designer (

www.hexagonmi.com) now features an Electrode module that offers ‘intuitive and simple dedicated functions’ that have been designed by engineers with experience in the mould and die industry.

These functions make it easy to use direct modelling commands and powerful ‘surfacing and healing tools’, and for electrodes from imported models to be extracted quickly, to create finer details on parts that cannot be machined using traditional milling techniques.

WorkNC Designer also brings an enhanced link to WorkNC Traditional, allowing the entire work zone to ‘be prepared’ before sending it to the manufacturing planning phase of the process.

WorkNC 2020.1 also brings an integrated link to Hexagon’s NCSIMUL simulation solution; this means that manufacturing data created in WorkNC is brought automatically into the application — including fixtures, roughed stock,

design part, program origins, machine programs, and the complete cutting-tool library.

Furthermore, with the WorkNC to NCSIMUL link interface, users can elect the Digital Twin Machine to prove out post-processed G-code programs.

This seamless process can transfer multiple part set-ups for verifying multiple operation G-code.