Axminster Tools has established itself as a market leader in the mail-order tools and machinery industry, having supplied premium-quality products throughout Europe for over 45 years.

This Devon-based family-built business has a heritage of UK manufacturing operations and has recently invested in a new sliding-headstock lathe to expand its already comprehensive array of machines and machining capabilities.

Having achieved steady year-on-year growth through product innovation, competitive pricing and a commitment to customer satisfaction, Axminster’s management recently decided to further enhance the business by investing in its manufacturing processes.

The upgrades were aimed at allowing the company to become more efficient, increase productivity and further develop its product range.

With an SR-32J and SR-38 Type B from Derby-based Star Micronics GB Ltd (

www.stargb.com) already on-site and a relationship with the machine tool supplier dating back over five years, Axminster’s supply chain director, Andrew Parkhouse, had no hesitation in consulting Star regarding the company’s latest project — chuck jaws for a wood-turning lathe.

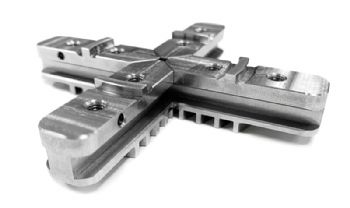

These jaws were first produced locally in small quantities over 30 years ago, but as demand increased, Axminster began sourcing the parts overseas to cope with growing volumes.

However, faced with quality concerns, the company brought the manufacture of these parts back in-house several years ago.

With the required production in the region of 25,000 units per annum, and current methods of manufacture requiring five operations — including milling, grinding and finishing — Axminster ‘challenged’ Star to produce the jaw in a single operation.

Its applications team was confident that the project could be undertaken on a sliding-head lathe and set about selecting the machine best suited for the job.

The cycle time calculation that Star subsequently established meant that Axminster would be able to produce the components more efficiently and increase profitability.

Turn-key package

The machine selected for this project was a Star SV-38R.

Axminster commissioned a turn-key package and began building an extension to its facility to accommodate the new machine, which combines the fast processing capability of a traditional platen-type sliding-head lathe with the flexibility of a turret machine to allow simultaneous machining operations.

The turret, which accommodates a substantial number of tools, features an independent Z3 axis that enables two different features to be machined at the same time, using Star’s ‘super-position’ control mode.

After comprehensive process development and by combining the machine’s balanced milling capability and specialist tooling up to 75mm in diameter, the manufacturing time was reduced by 60% compared to the previous method.

In addition to a shorter cycle time, component quality has also improved significantly as a result of ‘one-hit’ machining.

Mr Parkhouse said: “The SV-38R is a significant investment, and we are confident that it will allow Axminster to progress further; and while the machine will run these parts most of the time, we value highly the additional capabilities it gives us to develop other products in the future.

“Furthermore, the machine is freeing up significant capacity on our other machines, allowing us to maximise the machining potential of our business.”

Following the successful pass-off and delivery of the new machine, Axminster’s engineers underwent programmer training at Star, followed by on-site training in machine setting and operation.

Included in the turn-key package was Star’s PU-JR programming software.

This ‘editor’ makes programming the ‘three-channel’ machine more efficient, allowing Axminster’s setters to generate complicated programs quickly and easily.

Mr Parkhouse added: “Our machinist, Marika, has been with us a relatively short time but took an immediate liking to the Stars.

“She joined us with little machining experience but is now operating, setting and programming all of our machines.

“With Star’s help, she will be up to speed with the SV-38R in no time.

“Looking to the future, Axminster is forecasting continued growth, with an on-going investment strategy designed to keep the company abreast of the fast-moving industry it supplies.”