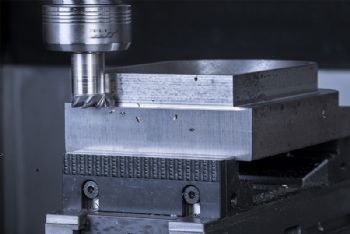

For exchangeable-head milling systems to achieve optimum performance, close attention has to be paid to the connection between the holder and the cutter head.

Ceratizit (

www.ceratizit.com) has optimised this interface with its new MultiLock system, which combines precision sintering of the cutter with a patented Captive Pocket.

A further benefit of this form-fit connection is that an axial and radial run-out accuracy of 0.02mm is achieved, while the combination of carbide head and steel body offers high levels of vibration damping for improved surface

finishes.

MultiLock targets applications such as those found in the mould and die, aerospace and hydraulics sectors, where complex contours are required and difficult-to-machine materials are common.

With conventional solid-carbide tools, as the diameter increases, so do costs.

The MultiLock exchangeable-head system reduces these costs by allowing one steel holder to be used with a number of carbide heads.

Application flexibility is also enhanced, thanks to the choice of milling heads available.

These include high-feed milling cutters, torus cutters and radius cutters in diameters from 12 to 25 mm; 45deg deburring milling cutters are available in diameters of 12 and 16mm. Furthermore, various screw-in adapters add even greater flexibility to the MultiLock system.

Customers have the choice of two carbide grades (CTPX225 and CTC5240), along with proven cutting geometries that cover most applications; both grades feature Ceratizit’s Dragonskin coating technology.

The PVD-coated CTPX225 features a tough fine-grain carbide grade that is suitable for universal use, while CTC5240 has a TiB2-based coating (titanium diboride) that makes it suitable for machining titanium and titanium alloys.

Adrian Fitts, business development manager at Sheffield-based Ceratizit UK & Ireland, said: “MultiLock meets a specific need in the market and brings with it certain cost and environmental advantages over solid-carbide milling cutters, especially in applications where longer reach is required.

"Cutting data is improved by virtue of the increased number of cutting edges that can be introduced, and with those cutting edges being produced by precision sintering technology, costs are also reduced.”

Further information and a product video can be found at the Web site (

cuttingtools.ceratizit.com/gb/en/multilock).