British car manufacturing fell -0.8% in February, according to figures just released by the Society of Motor Manufacturers and Traders (SMMT).

Some 122,171 vehicles rolled off production lines in the month, representing a loss of just over 1,000 units compared with February 2019 — the decline was driven by slower demand in some key global export markets.

In the month before the Coronavirus pandemic started to be felt in the UK, global shipments fell -3.1% to just short of 95,000 units.

Although combined European Union demand rallied (up +3.6%), exports to the US and Asia fell substantially.

Meanwhile, there was positive news for the domestic market, where output rose +7.8%, with 27,172 cars produced.

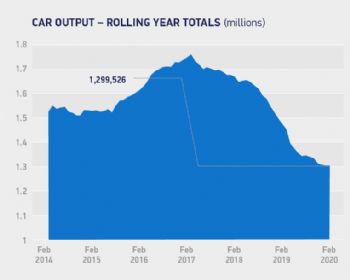

Year-to-date figures show a -1.5% year-on-year drop in overall production.

The figures come at a time of unprecedented challenge for the UK and its automotive industry, with all car manufacturing plants now on shutdown as the country focuses efforts on overcoming the crisis.

An initial assessment commissioned by SMMT of the potential impact of these shutdowns suggests a loss of around 200,000 units by the end of 2020, just under 1.1 million — a fall of 18%.

However, the impact could be far more severe if the crisis, and therefore shutdowns, were to last for months instead of weeks.

SMMT chief executive Mike Hawes said: “Despite the myriad global challenges the UK automotive industry has faced in recent times, it remains fundamentally strong and February’s figures reflect that.

“However, these figures also reflect the calm before the storm. With UK car plants now effectively on national shutdown and many global markets closed, the outlook is of deep concern.

“We wholeheartedly welcome the Government’s extraordinary package of emergency support for businesses and workers, but this must get through to businesses now.

“If we’re to keep this sector alive and in a position to help Britain get back on its feet, we urgently need funding to be released, additional measures to ease pressure on cashflow and clarity on how employment support measures will work.

“The automotive industry is one of the UK’s most valuable economic assets, contributing some £18.6 billion to the economy every year and employing hundreds of thousands of people across every region of the country in high-skilled, high-value jobs.

“Despite the current challenges, the entire industry stands ready to help the national effort, from production of essential medical equipment, to sustaining delivery of essential supplies, providing and maintaining emergency services vehicles and transporting key workers.”

Reacting to the latest figures, Rahul Chalisgaonkar, principal for manufacturing at Infosys Consulting, said: “A turbulent time lies ahead for the British car industry, as the Society of Motor Manufacturers and Traders warns production will be down by at least 18% this year due to Covid-19.

“As factories shut up shop and global markets close, this will inevitably make a significant dent to the world economy, with big impacts on manufacturing and supply chain dependent sectors.

“However, car brands have a significant part to play in the Coronavirus outbreak.

“Many, including Rolls Royce and Jaguar Land Rover, are working with the Government, converting their plants to manufacture ventilators and other crucial medical supplies to ease pressure on the NHS and help save lives.

“Agility is key for organisations during this time and beyond, both in terms of manufacturing and supply chains. Adopting digital technologies like 3-D printing, which can be used to manufacture raw materials, or required parts, can soften the impact to the supply chain and ensure production doesn’t ground to a halt.

“Meanwhile, the logistics network can be managed more effectively through the use of AI (artificial intelligence), which can deliver automated insights in real-time on how to re-route fleets and make those all-important deliveries happen.”