Simulation software from Hexagon that reads the post-processed G-code to identify machining tool-paths is helping PCI-SCEMM to improve productivity by up to 30%.

According to Hervé Damon, head of machining process studies, the company first invested in NCSIMUL (

www.ncsimulcom) in the late 1990s.

He said: “Since then, we have continued to improve our methodologies; and thanks to the team at Hexagon, we are further improving our controllers and virtual machines to keep pace with the evolution of Fanuc and Siemens numerical controls — and physical machines.”

PCI-SCEMM develops machining solutions for the mass production of conventional powertrain parts such as cylinder heads and gearboxes, as well as battery-trays and e-housings for e-mobility powertrains.

The company is located in Saint-Étienne, on an industrial site hosting the Higher Institute of Performance Techniques engineering school.

Mr Damon continued: “Our service to customers is based on the combination of high-performance machining centres associated with innovative and robust machining processes. Simulation with NCSIMUL allows us to propose more-profitable technical and economical solutions that require fewer machines, giving us a real competitive advantage.

Each of our projects is unique and a real challenge, so we need to create tailor-made machining programs that exploit 100% of the machines’ capacities, adapt 100% to the parts to be machined, and take into account 100% of the customer’s constraints.

As a result, we over-optimise each line of code to ensure fast and efficient set-up, coding directly in ISO and then validating the program with NCSIMUL.

“Thanks to systematic simulation — upstream during pre-studies and then downstream during programming — all processes simulated in NCSIMUL are deployed without collision, with no accessibility issues and no unnecessary travel.

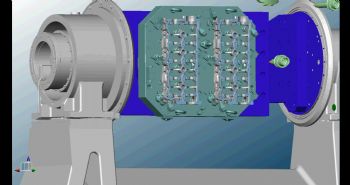

“About 50 programs were produced during 2019, using proven methodologies based on around 100 versions of virtual machines; these are real ‘digital twins’ that allow us — via an ISO code — to link the virtual world to the physical world.

“Thanks to the flexibility of custom manual programming, we can optimise the use of the signals from all the physical sensors integrated in our machines — such as part temperature and spindle power.”