A lightweight fuel tank for small-scale satellites has been designed and developed by metal additive manufacture engineers at the University of Sheffield Advanced Manufacturing Research Centre (AMRC) as part of a pioneering UK Space Agency-funded programme.

With the annual number of small satellites deployed forecast to reach around 400 this year – an increase of 300% compared to 2016 – there is growing demand to dramatically expand mission capabilities, extend orbital life and decrease the cost of constellation deployment.

AMRC engineers used topology optimisation techniques to reduce the weight of the tank by over 25%, combined with an almost three-fold increase in fuel capacity over conventional spheroidal storage tanks which could result in significantly reduced satellite launch costs.

Abdul Haque, technical lead in metal additive manufacturing at the AMRC, said: “Developing competitive propulsion solutions for small satellites is a game-changer for our UK space capability. The MiniTANK project lays the groundwork for adding a key miniaturised, low-cost propulsion technology to the UK’s portfolio.”

MiniTANK is a collaborative project between the AMRC and Oxfordshire-based Added Value Solutions (AVS) UK Ltd, a company that designs propulsion systems for small-scale satellites, to develop a propellant storage system for a nanosatellite that maximises the internal volume while minimising mass – using novel features that can only be manufactured through additive manufacturing (AM).

Propulsion systemsBacked by the UK Space Agency’s Pathfinder programme, AMRC researchers have produced a lightweight, high-strength fuel tank for a cube satellite (CubeSat) that meets the demanding performance and cost targets desired by AVS which chose to work with the AMRC’s design and prototyping group (DPG) because of its leading expertise and experience in designing AM parts. In return, MiniTANK has given the AMRC an invaluable foothold in the UK space industry and provides a significant new offering to current and future industrial partners.

Daniel Staab, AVS UK system engineer said: “Using a pressurised tank without the AMRC’s work on AM optimisation would have forced us to choose between a heavy design or a volume inefficient tank holding much less propellant in CubeSats.”

Mr Haque explained that MiniTANK has successfully demonstrated that metal AM is an alternative route for the manufacture of complex fuel tank designs: “The final AM fuel tank mass was 360g which was a 28% decrease in weight when compared to the original dry mass of 500g for a conventional tank. The volume utilisation (amount of usable space within the tank) was estimated at 90% which is an improvement when compared with spherical tanks at approximately 60%. It can hold approximately 2.8 times the fuel volume of a 78mm diameter sphere, which is the largest size that could fit within the allocated design envelope.

“During testing, the fuel tank withstood all non-destructive tests without observable deformation. It ruptured at a test pressure of 74 bar, which is 1.9 times the safety factor of the design burst pressure specified in the European Cooperation for Space Standardisation (ECSS). We were able to demonstrate the successful application of AM to achieve performance benefits of a component, the geometry of which is not possible to produce through conventional manufacturing methods.”

Current nanosatellite and microsatellite propellant storage systems use volume-inefficient but structurally strong cylindrical and spherical tanks. This means there is much interest in the development of fuel tanks, currently one of the heaviest components of a CubeSat’s propulsion system.

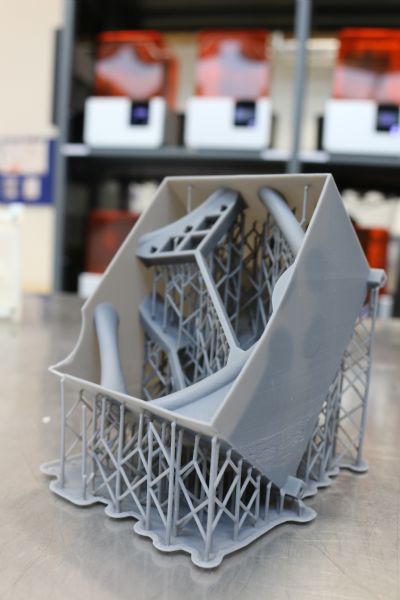

Mr Haque said the purpose of the MiniTANK project was two-fold: first to show it is possible to design an improved fuel tank but also demonstrate what can be achieved by using the AM process to do this. He continued: “With AM you can create complex forms that you cannot manufacture via conventional methods and the concept we generated was a cuboidal fuel tank. Through the concept developments we did in-house, using software tools such as Altair Inspire, Autodesk Netfabb Simulation and PTC Creo Simulate, we were able to assess the design space and identify areas for optimisation; for example where material from low-stress areas could be moved and placed in high-stress regions where more material is required.”

AM in the Cubesat marketKyaw Swar, AVS UK mechanical engineer, said: “This project has allowed us to understand much better the requirements and objectives of AM in the Cubesat market, which is crucial for other developments around mechanisms and optomechanical systems for small satellites that we are involved in.”

Mr Haque concluded: “Although this project focused on the fuel tank – if you take a system-level approach and carry out the same optimisation to other components of the CubeSat – the microwave generator housing, the propulsion system, brackets that connect solar panels, the framework – you are shaving weight off every assembly component. In total that might save a lot more material, so MiniTANK is not an isolated case, we should be looking at the entire satellite system to get the maximum benefits offered by AM.”