Sheffield-based Ceratizit UK & Ireland Ltd (

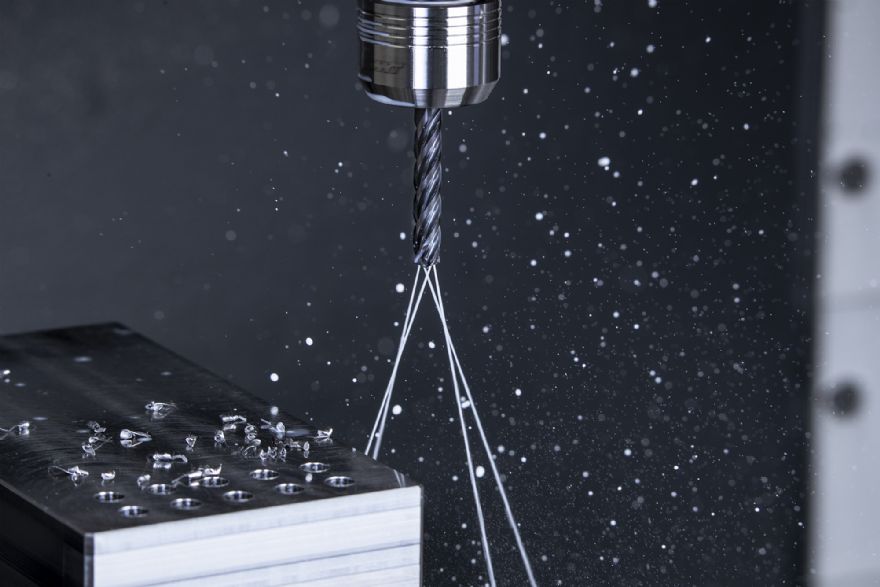

www.ceratizit.com) says that its WTX HFDS drill is the first four-edged high-feed drill on the market. Felix Meggle — the Ceratizit Group’s product manager (drilling tools) — said: “No matter what we put it up against, the WTX HFDS is faster every time, with machining times cut by up to 66% in comparison with standard two-edge and three-edge high-speed and high-feed drills.

“However, the WTX HFDS is about far more than just speed and productivity; it also delivers high quality in terms of positioning accuracy, tolerance and the roundness/cylindricity of the holes produced.

“For example, an average positioning accuracy of 0.03mm for the entire hole depth can be achieved; given the elevated cutting data, that is a significant achievement.”

A WTX HFDS 6.80mm-diameter drill with a 5xD flute length, drilling 1.7331/16MnCr5 steel at a surface speed of 120m/min and a feed rate of 0.50mm/rev, can produce holes to an H7 tolerance. This is possible due to the innovative pyramid-shaped drill point, which is completely unlike a conventional chisel edge and allows for “exceptional centring” of the drill.

The performance of the drill is assisted by the four continuous-spiral coolant holes; these maximise coolant delivery to every cutting edge, while maintaining the drill’s core strength and stability.

In addition, the drill produces only a slight burr when entering and exiting a hole. WTX HFDS drills also feature Ceratizit’s Dragonskin DPX14S coating — a TiAlN nano-layer that can withstand temperatures of up to 1,000°C.

These drills are available from stock in diameters from 6 to 16mm. Deliveries commenced in May, coinciding with the publication of Ceratizit’s latest Up2Date catalogue.