Specialists in IIoT (Industrial Internet of Things) and Industry 4.0 at the Manufacturing Technology Centre (MTC —

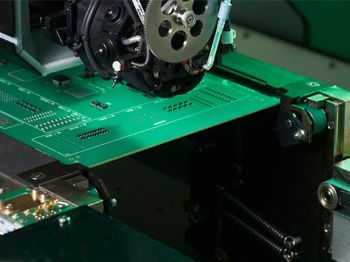

www.the-mtc.org) have developed the first stage of Europe's first smart factory demonstrator for the manufacture of electronic assemblies, helping electronics manufacturers “go digital”, transforming their businesses, and meeting the demands of an increasingly challenging market.

MTC's digital engineering experts are working with key vendors to develop and evolve a range of digital processes that help electronics manufacturers improve productivity and quality, while becoming agile to meet the most aggressive time to market constraints.

To power the smart factory demonstrator, MTC is using IPC Connected Factory Exchange (CFX), a standard developed by the IPC Connected Factory Initiative Subcommittee, which enables industrial machines to communicate with other machines and systems, across manufacturing facilities including the supply chain, using standardised machine communication message sets.

IPC CFX provides the baseline, powering the development of the MTC demonstrator test bed for electronics manufacturing. Any electronics manufacturing business is able now to trial and experience digital technologies in a risk-free environment, without disrupting day-to-day production.

The project is supported by OEM and technology supplier members of the MTC from a variety of industrial sectors, ensuring the project has industry steer as well as the latest in technology, which has been integrated and proven within the demonstrator — this includes technology such as augmented reality (AR).

Naim Kapadia, MTC technology specialist, said: “Our goal is to showcase products going through a ‘state of the art’ digital production line, collecting data from each station and machine, creating visibility, and showing the value that can be obtained from the many uses of the data.

“It is essential for industry to understand that digitalisation can now be achieved using interoperable standard components, which yield immediate results and short-term ROIs, which are best seen to be believed.”