An affordable ‘stopgap’ ventilator which can be used with minimal training could help keep seriously ill people alive long enough to either recover or receive hospital care, according to scientists at the University of Glasgow (

www.gla.ac.uk).

The device, called GlasVent, was developed by Professor Ravinder Dahiya and a team of engineers from his Bendable Electronics and Sensing Technologies (BEST) group at the university.

They began working on the project in mid-March, during the early stages of the UK’s COVID-19 outbreak, when demand for ventilators was expected to outstrip demand within weeks and anaesthetists and intensive care consultants were working flat-out on patient care and service redesign.

The University of Glasgow team turned to surgeon Professor Andrew Hart, who had previously worked with them to design bionic hand prosthetics, for help with basic medical advice.

Although demand for ventilators did not outstrip supply as feared, the team believe their design could still play a life-saving role in emergency medical settings. It is low cost, and manufacture could be rapidly scaled to allow basic ventilatory support for large numbers of patients if there is a second wave of COVID-19 later this year, or if other pandemics break out in the future.

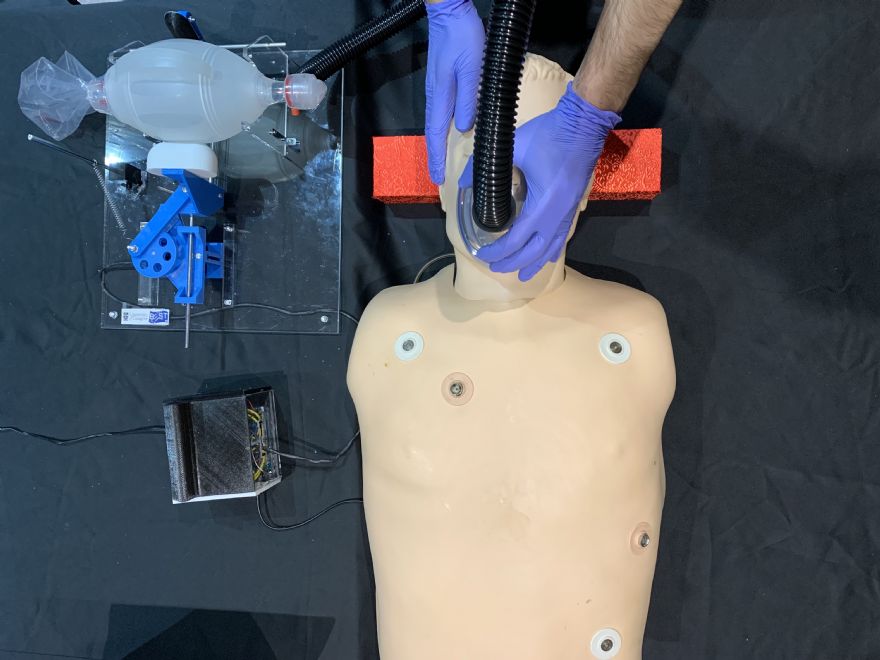

GlasVent aims to provide a simple, easy-to-use, and affordable method of delivering oxygen to critically ill patients. Its primary component is a bag valve mask – a hand-held, balloon-like device which is already commonly used in emergency medical situations. Users squeeze the device by hand to pass air through a tube, which helps to inflate patients’ lungs and keep oxygen circulating.

In theory, bag valve masks can be used indefinitely. However, they require constant attention and the amount of oxygen delivered with each compression can vary from squeeze to squeeze.

The GlasVent team have developed a way to automate the squeezing of the bag, allowing medical staff to concentrate on other aspects of care and standardising delivery of oxygen into patients’ lungs.

The system’s affordability comes from its unique mix of high and low-tech parts. The high-tech part is an Arduino micro-controller, which controls the pressure in the patients’ airways to ensure they receive the correct volume of oxygen with each compression of the bag.

The low-tech part is a 3-D printed slide-crank, a design similar to that found in steam engines. The Arduino also controls the motion of the crank, providing a squeezing action on the sides of the bag to deliver oxygen to the patient. In the event of a power outage, the crank’s simple design allows medical staff to operate it by hand, helping to keep the patient alive.

Professor Dahiya, of the University of Glasgow’s James Watt School of Engineering, said: “When the seriousness of the coronavirus pandemic started to become clear, my research group and I were keen to do whatever we could to help save lives.

“We are proud that we have managed to go from design to build to testing in a matter of weeks. We have already conducted numerous successful tests on a medical mannequin fitted with artificial lungs, provided by the Royal Alexandra Hospital Paisley, and are confident that it is fit for purpose.

“We hope that once we receive regulatory approval, GlasVent could be used not just to buy some more time for critically ill patients to either fight off disease or be put onto a mechanical ventilator, but to find use in care settings and in the developing world.”