A number of new and enhanced functions have been configured to keep the latest ‘digital twin’ software from Hexagon’s Manufacturing Intelligence division at the forefront of Industry 4.0 Smart Factory technology.

By increasing CNC program quality through automatic and predictive analysis, NCSIMUL (

www.ncsimul.com) virtually builds the real-life machining environment to avoid errors, reduce set-up times and switch CNC programs between machines.

The 2021 release features a new comparison mode that detects excess material during a fast and hidden simulation.This shows a solid comparison between the CAD/CAM models (or previous cut stock) and the NCSIMUL simulated model.

Technical director Philippe Legoupi says that this new function detects unwanted rest stock on a large part. “It shows a list of the excess material that’s left and can also be displayed in a 3-D window linked to the list.

“The benefits offered include: finding small missing drill holes on large aerospace components; and finding missing holes that need to be connected on mould bodies and hydraulic parts.

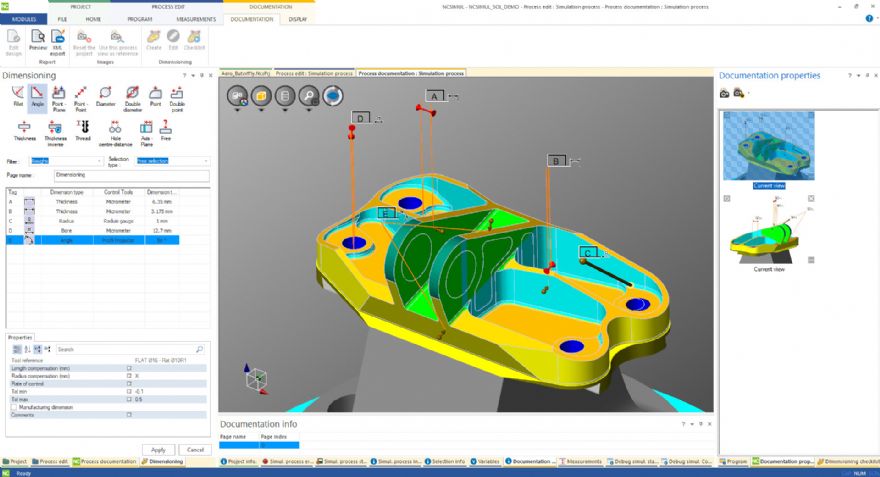

“Integrated to NCDoc, ‘Dimensioning’ is a new function that creates control instructions for operators during the CNC process. It defines a dimension check-list with user-defined tolerances, automatically defines the minimum measurement needed for each cut, generates a comprehensive view for the programmer and operator on the 3-D simulation, and works with the NCDoc documentation template.

“This function saves time and money, particularly when using the Wizard to create the correct number of measurements — even when using a probe tool on the machine.”

There is also a new set of options for quickly evaluating tools that can benefit from air-cutting optimisation, while enhancements to ‘editing Setup’ reduce simulation time by merging fixtures, parts and rough stock elements from one or multiple CAD files read in NCSIMUL.

Moreover, improvements have been made to mill-turn tooling management for ESPRIT CAM and TopSolid CAM interfaces. For example, with a new ‘Configuration interface file’ associated with each ‘digital twin’, it is now possible to define the mapping of tool assembly positions — station number, turret and orientation — between the CAM system and NCSIMUL.

Furthermore, a simplified 2-D display for turning parts improves the analysis of dynamic rough stock, while cutting-tool wear simulation can be applied to tools that are either ‘fresh out of the box’ or ‘worn down’.

User-defined values apply for each cutting tool, and the system can check if a worn tool will generate alarms or collisions with unwanted rest stock material.