Igus

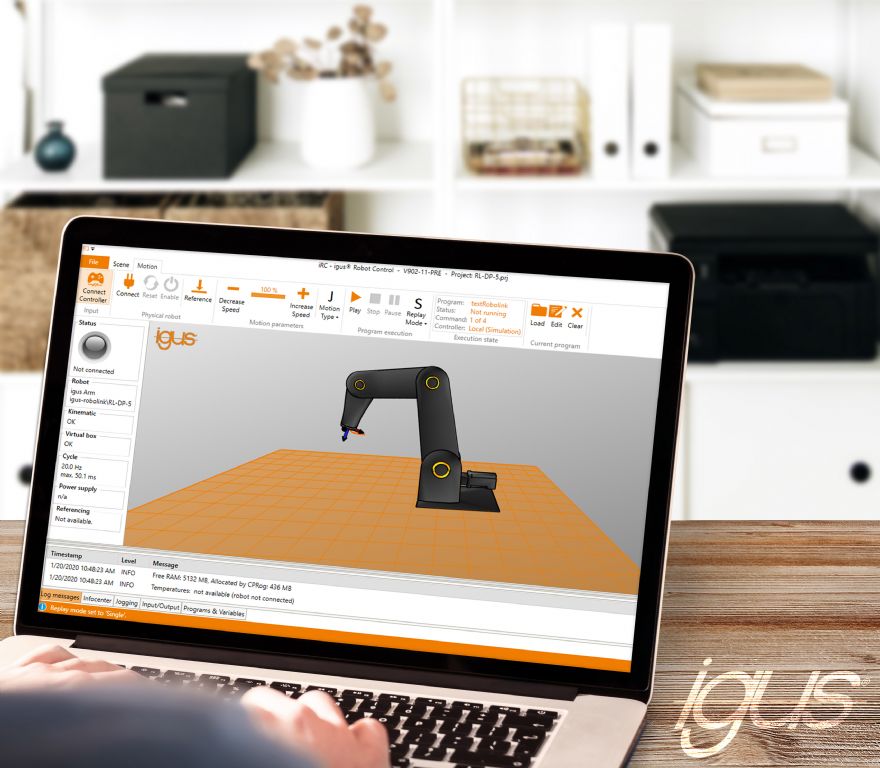

Igus has developed control software for its low-cost automation solutions that allows users to easily program their robots. Available on-line and free-of-charge, the software enables different robot kinematics to be programmed and controlled through a digital twin that simulates its movements, allowing the user to program a suitable solution before purchase.

Picking up goods from a box, helping to take samples and dispensing items from a machine can all done by robots. Whether it is articulated robolink robot arms, drylin delta robots or drylin linear robots, users can try out in advance which robot is best suited for their application.

Robert Dumayne, dry-tech director, said: “As a mechanical engineering company, we are very familiar with the different kinematics, so the next logical step for us was to develop a correspondingly simple and intuitive robot control system. The software is available on-line free of charge and is licence-free.”

In the software there is a digital twin for all Igus robots, which can be simulated and taught like a real robot.

Matching end effectors, such as grippers, are easy to add and the tool centre point adjusts automatically. Virtual boxes can also be installed, for example, to prevent the robot from colliding with a machine; the robot control can also be connected to a higher-level control system, either via interface communication with Digital IO or via Ethernet communication using an IP address — every program can be applied to the real robot afterwards.

For more information about igus’ Robot Control system, please visit the Web site (

www.igus.co.uk/info/robot-control-system) or telephone Igus on 01604 677240.