Tewkesbury-based

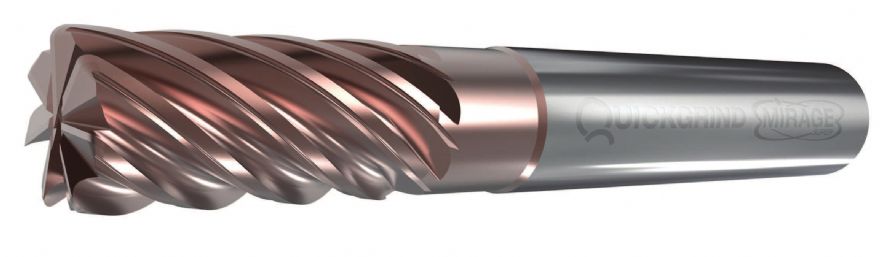

Quickgrind Ltd has extended its product offering with the introduction of its new Mirage Super range of solid-carbide end mills.

Designed for a variety of applications in a wide range of materials, these cutters are available in standard or application-specific formats for the high-performance machining of stainless steels, titanium and super alloys.

Based on the existing series of Mirage cutters, the latest Super types feature Quickgrind’s next-generation coating technology and the very latest micro-grain carbide substrate.

They are available with four, five or six flutes (more for specific applications and sizes) in diameters from 3 to 32mm and with various combinations of edge preparation radius, chip breaker, through-coolant or neck reduction, to allow for optimised machining processes — including trochoidal milling applications with full flute engagement at 3xD.

Quickgrind’s new XRed-SL coating technology has been developed using advanced arc technology that deposits coatings at far higher energy levels than is possible with conventional arc sources.

This gives a significantly increased coating density, which results in improved abrasion resistance and a reduced tendency for chipping at the cutting edge.

This multi-layer TiSiN coating, which has fewer ‘growth’ defects for a smoother surface (this can be further improved with the appropriate post-treatment), has been developed for high-speed milling of the hardest and toughest materials under low lubrication and dry conditions.

It performs best on tungsten carbide tools, with which it can withstand temperatures of up to 1,100°C at the cutting edge.

Moreover, this new range of tools can be reground and re-coated by Quickgrind a number of times as part of the company’s remanufacturing service.