Loiretech Ingénierie is a French company based at Bouguenais which specialises in large complex tools for the commercial aerospace, automotive, defence and energy industries.

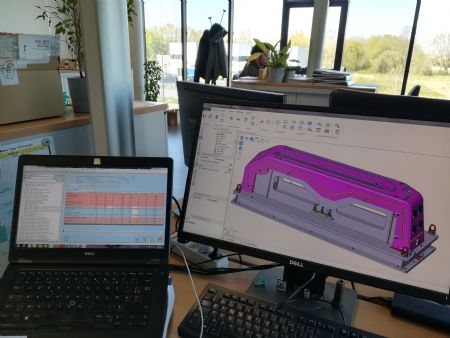

The company has resolved its design, manufacturing and production control processes by seamlessly merging three products — WorkNC, WorkPlan and WorkXplore — from Hexagon’s

Manufacturing Intelligence division, to create one integrated solution that connects all its ‘business silos’ together.

Machining manager Stéphane Haoui, said: “Accuracy of programming is essential for us. If our CNC programs aren’t accurate, it would be catastrophic.”

Loiretech produces a range of composite and metal tools for forming, thermoforming, moulding and part inspection; these include moulds for the production of reactors, fuselages and structural parts. The space market is also catered for, in particular through the production of tools for ‘satellite reflectors and rocket fuselage reflectors’.

The company also manufactures blades and propellers for the naval industry, using nine machines (comprising Zayers, FPTs, Forest Lines and a Rambaudi) that are programmed by Hexagon’s WorkNC CAM software.

Mr Haoui says this is fully integrated into all stages of manufacturing — analysis, comparison, simulation, verification and machining.

“Tool paths are programmed using WorkNC’s roughing, re-roughing, semi-finishing, finishing and cornering functions. The software automatically displays the stock in real time as the workpiece moves forward throughout the machining process.

“In order to secure the whole process before starting machining, we simulate the tool-paths to check there are no collisions between the machine, the part, the cutting tool and the tool holder. It used to take two days to program a part with 300 holes; now it takes less than 2hr.”

Meanwhile, WorkPlan keeps track of all Loiretech’s business operations. For example, the company’s ‘Research and Innovations’ department uses the enterprise resource planning (ERP) functions to ensure an accurate follow-up of costs and comparison with allocated budgets. The software, which was installed in 2016 and has been updated with each new revision when released, is now used by most departments.

These include the workshop, which has numerous touchscreens for employee management and incident reporting via CMMS (computerised maintenance management system).

IT manager Sébastien Fraquet said: “WorkPlan is the backbone that allows us to structure our services. It can be found at every level of the company, and we manage everything with it — from quotation to final invoicing, including purchasing management, non-conformity management and personnel management. Different departments know the costs they are generating and react quickly to preserve and increase the company’s profitability.

“Controlling the purchasing process with the ‘Purchasing and Inventory Management’ module, along with supplies and materials from our Catia multi-platform software suite, a Bill of Materials is created and imported into WorkPlan, allowing us to manage requirements efficiently through the buying department.

Another important feature is the ‘Order Status’ module, which lets us know how much we are getting back for everything we have on the shopfloor, both in terms of hours spent on jobs and the volume of purchases.”

Also boosting Loiretech’s efficiency is Hexagon’s WorkXplore CAD viewer, which allows the company to open all types and sizes of CAD files and both import and analyse them at high speed.

Mr Fraquet added: “The sales and projects departments open Catia and other CAD files with WorkXplore in order to analyse and cost projects. In addition, the workshop uses it for assembly and measurement applications. Some vital information isn’t visible on 2-D plans, but with the workshop having the full 3-D file we avoid additional costs caused by assembly non-conformities.

“Our sub-contracting department also uses WorkXplore. Because some tooling parts are machined elsewhere, 3-D files are sent by e-mail — together with additional annotations and any necessary supporting drawings — to ensure the sub-contractor has all the necessary information.”