The future of advanced manufacturing in the UK hinges on investment in applied research, Labour leader Sir Keir Starmer said on a visit to the Welsh Government’s £20 million R&D facility in North Wales run by the University of Sheffield Advanced Manufacturing Research Centre (AMRC).

Mr Starmer toured the facility – next door to the Airbus wing manufacturing plant in Broughton – with the Welsh government’s First Minister, Mark Drakeford, and Shadow Chancellor, Anneliese Dodds, where the Labour leader discussed the future of jobs at the plant with Airbus executives.

He pointed out that ‘top class’ R&D talents of AMRC Cymru are critical success factors for the future of both Airbus in North Wales and the UK manufacturing sector more widely.

Mr Starmer said: “What you see at AMRC Cymru is the future of manufacturing and I think that is very inspiring. If the R&D here is top class, which it is, then that means that those highly skilled jobs will stay in North Wales.”

The Labour trio were shown presentations on how the AMRC is working alongside Airbus on its Wing of Tomorrow programme as well as how engineers at the AMRC used Industry 4.0 technologies such as Discrete Event Simulation, automation and virtual reality (VR) to pivot their operation to mass-produce thousands of medical ventilators.

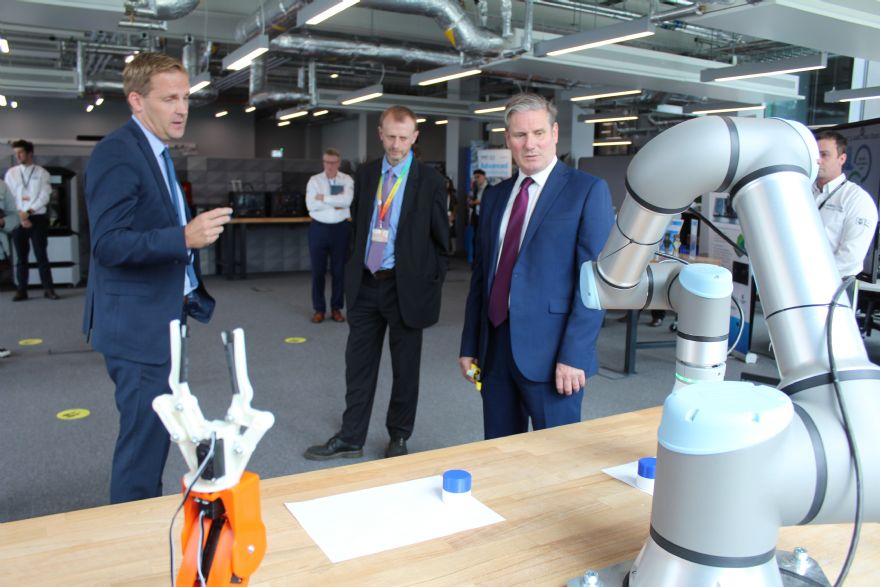

They were also shown the AMRC’s capabilities in additive manufacturing, augmented reality (AR), Hydrogen, composites, robotics and a new package of work being done alongside Food and Drink Wales.

Mr Starmer continued: “Places like this are really important — making things matters. It is incredible in terms of technology, development and testing but also critical to the importance of Airbus and what goes on here in North Wales in the long term. What is happening here hopefully ensures the future of manufacturing in ten years’ time.”

“Manufacturing and advanced manufacturing is very important to the UK economy. My father was a tool maker in manufacturing and he impressed on me the importance of making things. What I have been really pleased to see in the last few years is how manufacturing has moved on so much – it is why we need to work now to preserve those jobs.

“We have moved from a manufacturing sector that didn’t, in my opinion, work particularly well decades ago, to a manufacturing system which is smart and world-leading; we need to retain that.”

Mr Starmer said key to that success is the research and development being done at places like the AMRC: “The manufacturing sector needs to be underpinned by R&D. We wouldn’t be where we are without R&D and we won’t be where we need to be in a decade without it. Without R&D you are actually suffocating manufacturing.”

Darren Reynolds, Broughton site convenor for Unite the Union, said those effusive remarks about AMRC Cymru are reciprocated by engineers on the shop floor at Airbus as well.

He said: “We can try things at AMRC Cymru that otherwise we would have to do on the shop floor, whether that is new tooling or new methods of working. What we have here is the ability to try it, test it, de-risk it and then put it into manufacturing.”

“It is vitally important for the future of manufacturing that we can learn from procedures before we go into production - it speeds everything up and keeps us one step ahead. You have to embrace new ways of working and for us to have this on our doorstep means we will use it to its full advantage and it will only be good for the site.

“The facility can only improve Unite members here in Broughton and put us one level ahead; it will give us more opportunity within the company and it will be fantastic.”

AMRC Cymru was opened in November 2019, backed by a £20 million investment from the Welsh government, and is the first High Value Manufacturing (HVM) Catapult centre in Wales.

AMRC Cymru operates a 2,000m

2 open access research area with Airbus the first major tenant with a platform to develop their next generation wing technologies aligned to its ‘Wing of Tomorrow’ programme.

In March 2020 AMRC Cymru was transformed into a production facility for life-saving medical ventilators by the industrial consortium Ventilator Challenge UK. In fewer than two weeks, the ‘state of the art’ research institute was stripped out to allow 88 operators to work simultaneously while maintaining safe social distancing and allowing shift breaks and lunch times.

Mr Starmer added: “What we learnt from the Ventilator Challenge UK consortium was the adaptability of manufacturing to go from building wings of aeroplanes to ventilators in a matter of days.

“On top of that, thinking through the supply chains in the middle of a lockdown was quite incredible.”

Andy Silcox, AMRC Cymru research director, said: “That Sir Keir Starmer asked to see AMRC Cymru on his first visit to Wales as Labour leader shows the importance of advanced manufacturing and our facility to the area.

“It was great to showcase our work as part of the Ventilator Challenge UK consortium, but we also wanted to demonstrate how we can work with Welsh manufacturers to adopt innovative manufacturing technologies and help them reach new levels of productivity and sustainability.

He concluded: “The Covid-19 pandemic has demonstrated how agile manufacturers need to be to adapt to changing market demands and AMRC Cymru has the Industry 4.0 technologies to make that possible.”