Photo: ESO Y. Beletsky

Photo: ESO Y. BeletskyThe UK Astronomy Technology Centre is working on two separate instruments that aim to teach astronomers far more about the Universe than is known at the moment.

Some of the parts are being manufactured using tool-paths created by Edgecam CAD/CAM software, having been aligned to a high level of accuracy using a Hexagon Global CMM — both from Hexagon’s Manufacturing Intelligence division (

www.hexagonmi.com).

Will Taylor, an instrument scientist UK ATC, says the instruments will be fitted into the VLT (Very Large Telescope) at Chile’s Paranal Observatory, which is regarded as one of the ‘most productive ground-based telescopes in the world’.

One instrument, known as MOONS (Multi-Object Optical Near-infrared Spectograph), looks at many astronomical objects simultaneously and gathers information from them all at the same time.

Everything for this is being assembled by UK ATC (at its base in Edinburgh), which says this is a particularly novel and exiting project, as it will “allow astronomers to look at 1,000 objects at once and in the infra-red spectrum. It is the first time anyone has ever combined highly multiplex with infra-red.

“Because of the vast distances, the light we are seeing from stars now actually ‘set off’ millions of years ago; for the first time, MOONS will take scientists even further away — possibly round 10 billion light years — enabling them to build a map of a large section of the Universe.”

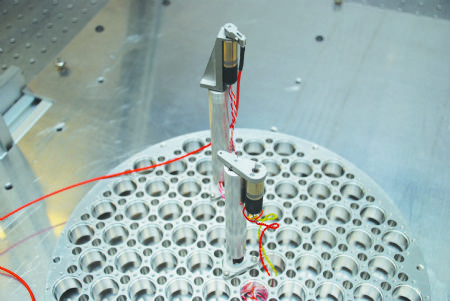

A thousand small robotic positioners lie at the heart of this instrument, which will be used to precisely align optical fibres with the target object.

Light is then fed along these fibres into a spectrograph, where it is split into three different wavelength channels, before being dispersed to simultaneously deliver ‘spectra in each channel’.

Major roleEdgecam and the Hexagon CMM played a major role in producing the highly complex components. Richard Kotlewski, the workshop technician responsible for manufacturing most of the 75mm square components for the calibration system that forms an essential part of the instrument, took a couple of hours to program them with Edgecam.

He imported the 3-D model and drawing into this CAM software, then decided how to manufacture the part, as well as which machine was going to be used.

“Next, I established the datum and used Edgecam’s Feature Finder function to let the software create the perfect tool-paths automatically. It was extremely important that the parts were highly precise, as accuracy is absolutely critical for their optical alignment.”

Because the parts are being used for holding optical components, calibration was vital to ensure the incoming light source goes to the correct place. This was achieved with UK ATC’s Hexagon Global CMM checking bores and positional tolerances of the components in the assembly.

The other VLT project is ERIS (Enhanced Resolution Imager and Spectograph), which will use the main telescope’s adaptive optics to “remove distortion from the atmosphere” as astronomers hunt for planets outside our solar system.

Mr Taylor said: “Effectively, it is taking the ‘twinkle’ out of the stars. This is achieved with a mirror that can have its surface shape adjusted hundreds of times a second, to give imaging quality that is incredibly high and has no distortion at all.”

Five-axis machiningUK ATC’s role as a member of the international consortium manufacturing specific mechanisms for ERIS was to build the new diffraction-limited camera system that couples on to the optics being produced in Italy.

Mr Kotlewski says some of the camera’s 6082-aluminium parts were produced on a five-axis Haas VF5 machining centre.

“Because of their complexity and the fact that some components have particularly thin walls, as we are restricted on the weight of this instrument, each part took about a day to program and two days to machine — such was the amount of material being removed.

“I used Edgecam’s Waveform Roughing strategy to make deep cuts while minimising stress because of the smaller step-overs, but still achieved optimum material removal rates.”

There was a different use for the Hexagon CMM for the ERIS application. Although UK ATC was not producing all of the components, it was responsible for the overall completed instrument.

“We had to take the parts we had made, along with parts from other consortium members, and ensure they were accurately aligned. The mechanisms had to be positioned within 10µm for everything to line up, and we used the CMM to ensure that level of accuracy was achieved.

“This work took over a week. Each individual mechanism was placed onto shims attached to the optical bench. Measurements were taken to determine the centre of the mechanism and to make sure it was square and parallel.

“Shims were then machined to bring the mechanism into the correct position. Without the CMM we could not have achieved this vital part of the operation.”