The world is ‘becoming flatter’ thanks to electric bicycles (e-bikes), which not only take the sweat out of conquering even the most challenging geographical terrain but also offer an environment-friendly form of ‘zero-emission’ transport.

Today, there are 200 million e-bikes registered in China alone, according to the country’s Ministry of Industry and Information Technology (MIIT), and 30 million more e-bikes are being added each year. From 2023, the rest of the world — primarily the growing markets in Europe and the USA — is expected to be buying around 6 million e-bikes per year.

Not surprisingly, China has more than 700 e-bike manufacturers, leading the world in both electric bicycle and electric vehicle production, accounting for 80% of global turnover. One of the market’s most popular e-bike drive units relies on a crankshaft featuring a splined chromium-steel axle that is machined on Tornos (

www.tornos.com) machine tools.

A good material choice for an axle that is subject to wear, it is an easy-to-machine steel that can easily be hardened after machining. The axle, which is turned as well as milled at both ends, plays ‘an essential e-bike role’ by securing the pedal on the crankshaft.

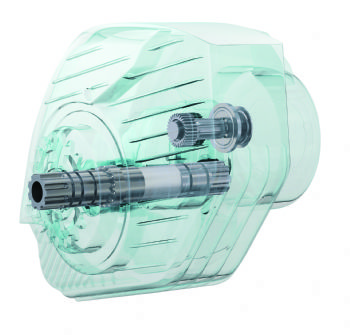

This is where Tornos’s EvoDeco single-spindle lathes comes into their own, quickly turning 148 x 20mm bars of 16MnCrS5 steel into highly precise splined axles. Tornos says the EvoDeco, which is available in four diameter ranges (10, 16, 20 and 32mm), is designed for the most demanding machining operations and puts the company’s gear-hobbing expertise centre stage.

The machine comes equipped with the latest-generation technology and features an identical main spindle and counter spindle (driven by an asynchronous motor) that gives acceleration rates and stopping times that are four-times faster than other machines on the market.

Furthermore, the machine structure, ball screws and guides are all heavily reinforced to make full use of the EvoDeco’s performance potential. Also featured are four completely independent tool systems, 10-linear axes and two C-axes. Moreover, programming is simplified, thanks to the TB-Deco and TISIS software solutions.