Matthew Garbet of MSC and Martin from Arrowsmith working together

Matthew Garbet of MSC and Martin from Arrowsmith working togetherAs a prominent Tier One sub-contract supplier to the world’s leading aerospace OEMs, Arrowsmith Engineering has a reputation for being a high-quality fast-response business that covers everything from R&D, machining and non-destructive testing (NDT), through to pressure-testing services.

Recently winning the Queen’s Award for International Trade that adds to a ream of awards, accolades and certifications, Arrowsmith has like most companies witnessed challenges throughout the pandemic. As a SC21 Silver accredited company with customer approvals from the likes of Rolls-Royce, GKN, ITP, Bombardier, Eaton and Meggitt, the pedigree of Arrowsmith is renowned.

For the Coventry company, the pandemic-induced challenges facing the aerospace sector has been overcome by diversifying and adapting to market forces and relying upon the expertise of its supply chain, and in particular MSC Industrial Supply Co.

Arrowsmith, like the entire aerospace industry, has witnessed the perfect storm of reduced orders and output, Covid-19-compliant distancing and temporarily forced staff reduction levels via the furlough scheme – a result of the world-wide flight restrictions.

However, the company has overcome numerous industry downturns during the past five decades, and this experience has seen it once again seamlessly adapt to market conditions. With MSC supporting Arrowsmith over the last five years to deliver cost-reductions and productivity savings of more than £500,000, Arrowsmith has again called upon its supply partner.

With the temporary dip in aerospace work, Arrowsmith was intent upon winning new business during the pandemic. The AS:9100 and ISO:14001 certified manufacturer tendered for a contract with an aero-engine OEM to undertake the machining of more than 50 aluminium engine components. The company turned to its supplier MSC to support the project.

MSC application engineer Matthew Garbett reviewed Arrowsmith’s proposed machining strategy for the parts and set about improving the process. Under normal circumstances, this is part of the daily job for any of MSC’s applications and engineering team – but with Covid-19 restrictions in place, he had to undertake the challenge remotely.

“Working as an extension of the Arrowsmith engineering team, he reviewed the proposed strategy for five set-ups on two three-axis machining centres and subsequently adapted the process to two set-ups on a single five-axis machine.

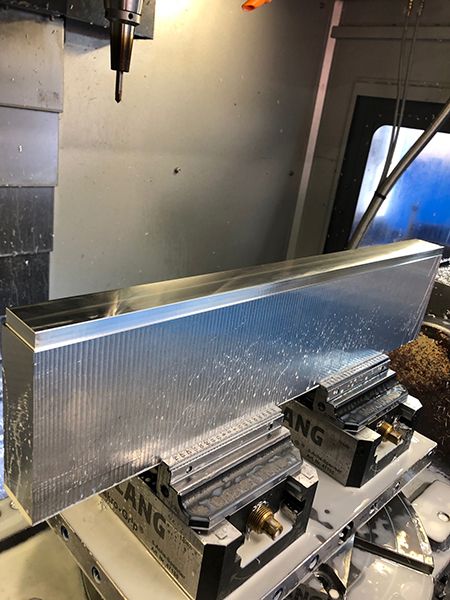

Mr Garbett was given the work envelope and axis movement dimensions of Arrowsmith’s Leadwell V40i five-axis vertical machining centre and intuitively configured a solution with workholding solution provider Lang Technik which included the adaptation of the existing zero-point clamping system to add a secondary clamping plate and two Lang vices for clamping the extra-long parts.

With the machine, work envelope, and workholding configuration defined, Mr Garbett was then supplied the CAD drawing and model of the component by Arrowsmith. He programmed the dimensions of the machine with Autodesk’s Fusion 360 package and then exported the data to Autodesk PowerMill to programme the toolpaths and machining strategy.

Mr Garbett said: “On the shopfloor, Arrowsmith uses Alphacam as its preferred CAM system. Our current library of post-processors was relevant to its Leadwell five-axis machine which meant we could provide a stable, secure machining process in PowerMill, that would be free from potential collisions while ensuring machining strategies were optimised.”

As well as remote programming and defining a machining strategy, it was important to select the right cutting tools to yield optimum results. The diverse portfolio of brands and a seemingly endless range of cutting tools available from MSC provided the optimal solution.

Mr Garbett explained: “Based upon the experience of MSC’s engineers, we know that machining aluminium aerospace components of this type would be best suited to the solid-carbide milling tool range offered by SGS Carbide.

“Sharing the details of the project with Steve Neale, a senior application engineer at SGS, we remotely created and optimised a selection of cutting tools that would enhance machining performance and tool life while consolidating the number of tools required.”

The MSC strategy was to face machine the top of the part and add the location features for the zero-point clamping system. The second set-up was to undertake the complete machining of the remaining faces, edges, pockets, chamfers, holes and threads.

The tools selected for the process were a Kennametal face mill with three indexable inserts that cost-effectively replaced a previous six-insert face mill, as well as a solid carbide Accupro drill and a DC Swiss threading tool.

Following the heavy material removal operation, MSC collaborated with SGS and used a series of two-, three- and four-flute solid carbide end mills, ranging from 2 to 16mm in diameter. Both square end and ball nose designations were used for machining all features, including edge radii, pockets and slots.

Once the first lockdown restrictions were relaxed, and site visits were allowed, an appointment was planned. With the CAM programme and post-processor in place, MSC’s Matthew Garbett and Steve Neale from SGS worked in collaboration with Arrowsmith engineers to set-up the machine, running preliminary parts and optimising the cutting speeds and feeds in accordance with the parameters of the machine.

While the machining strategy was in place, the cutting speeds and feeds had to be tweaked on the machine, as the workholding set-up and machining strategy had the potential for part deflection.

By undertaking the project remotely, MSC has seamlessly integrated this complex machining process into the shop floor at Arrowsmith. By adapting the machining strategy to just two set-ups, MSC has guaranteed process stability for critical aerospace components with tolerances across the part tied to less than 50µm.

As well as ensuring process stability, MSC has instigated a machining strategy that is yielding a cycle time of just 2hr 20min for the extremely complex parts while demonstrating exceptional surface finishes.

Furthermore, by utilising specific cutting tools from SGS Carbide, Accupro and Kennametal, MSC reduced tooling costs and consumption via improved tool life and greater flexibility and autonomy for all aluminium machining tasks.

Martin Porter, Arrowsmith general manager, said: “MSC has collaborated with us on several complex projects over the last four years and shares our ambition to be the best we can be. Like us they see the importance of creating efficient and cost-effective processes at every stage of production.”

MSC’s national account manager Oliver Latchford concluded: “Conducting remote working to such an extent has been a true testament to the expertise MSC engineers have, and also our relationships and understanding of our customers and their needs.

“In this instance, Arrowsmith approached MSC with set criteria, and we have successfully fulfilled and exceeded the requirements. More manufacturers are bringing MSC engineers into the manufacturing process at a much earlier stage than ever before.

“Customers are calling upon MSC to support them right at the ‘new product introduction’ phase. By utilising our expertise and solutions at such an early stage, we can yield huge benefits for the end users, and this is why MSC is a partner of choice.”