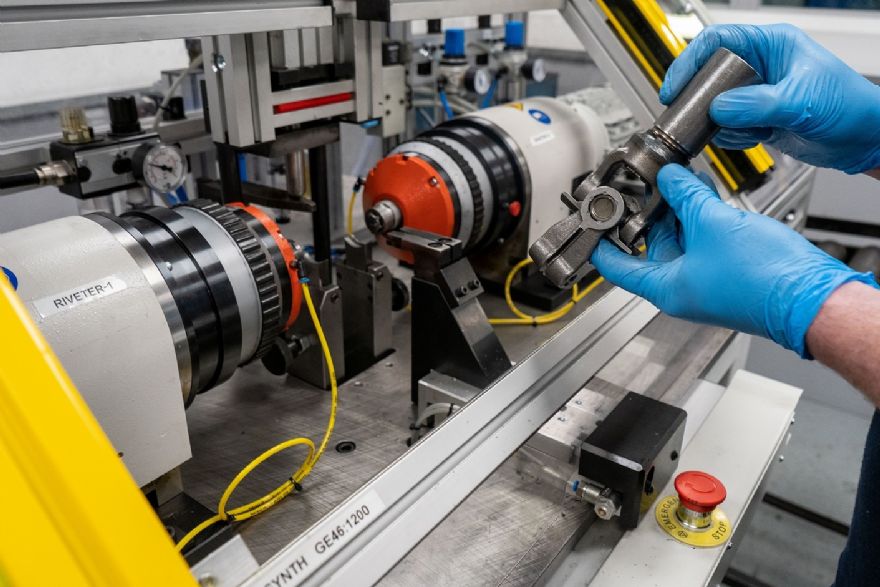

The basic principles behind the universal joint have been around for centuries, but the methods behind their manufacture are changing. Nick Jordan, head of engineering and quality at the steering system specialist

Pailton Engineering, says an assembly process at its headquarters in Coventry has helped the company improve consistency and longevity of the universal joints it manufactures for specialist vehicles.

He said: “Universal joints play a critical role in the steering system, transmitting rotational input torque through the entire steering system via varying angles, at a consistent speed, without resistance or radial play. Get it wrong, and the vehicle can suffer from reduced steering precision.

“Traditionally, universal joint assembly involved combining a bearing assembly inside two yokes using a high-pressure press and a highly skilled operator; and while this method of ‘staking’ universal joints is still widely used and is fit for purpose, it has its limitations.

“Manual processes are vulnerable to human error, while applying high-pressure force to a material can affect its physical integrity. That is why Pailton Engineering has invested in two bespoke universal joint staking rigs that transform the manual process into an automated one.”

The two machines can run simultaneously, to stake 19mm or 15mm universal joint variants to an assured level of quality and consistency, with every universal joint in a batch assembled to the exact same high quality standards. Moreover, data recorded by the machines offers full traceability to show how the universal joint was built, including assembly pressure parameters.

Mr Jordan concluded: “With this more-controlled method of staking universal joints, we have been able to significantly reduce the pressure used within the process compared with the manual method, while maintaining optimum joint operation and quality.

“This offers a multitude of benefits providing a higher quality and longer lasting part for the end-user. The equipment has been installed in a purpose-built clean room work area that is solely focused on universal joint assembly.”