Kerf Developments

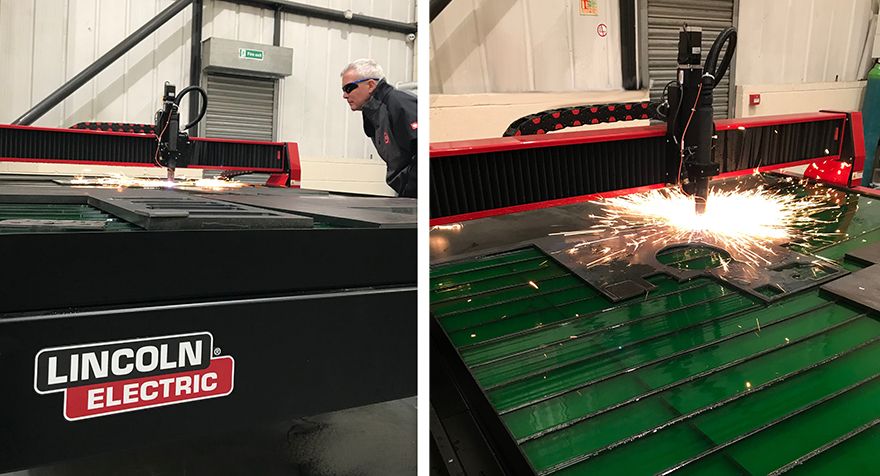

Kerf Developments has introduced the new Linc-Cut S 1530W ‘plug and play’ plasmas cutting system which is designed and developed by US-based Lincoln Electric, a leading international supplier of cutting and welding equipment. The new machine is billed as straightforward to install, set up and operate.

Considered ideal for cutting mild steel and stainless steel plate up to 1.5 x 3m, the flexible Linc-Cut 1530 makes high-speed plasma cutting affordable and attainable for small metal fabrication firms, sheet metal contractors, custom vehicle fabricators and prototyping companies.

Kerf Developments will be supplying and commissioning the machines and providing training for the operators, together with service, support and spares from its headquarters in Rochdale.

Parts that customers may want to manufacture on the machine can be input using a variety of methods and the CAD software supplied as part of the turnkey package enables users to draw components. The system also allows users to import parts in standard file formats such as DXF or DWG.

Pre-loaded into the software is also 36 standard parametric shapes that include everything from simple adjustable rectangles through to complex circular flanges to simplify and speed up part programming.

Once drawn, the system can nest components with the potential for manual or automated programming for maximum material usage and cost savings.

The Linc-Cut 1530W is fitted with the latest Lincoln Electric Flexcut 125amp plasma system which offers excellent cutting and marking performance with a very low bevel angle and an impressive cut quality. Adding to this is impressive productivity levels with the machine above 5,300mm/min.

From an ease-of-use perspective, Accumove CNC motion control technology provides increased processing power and synchronisation of each component on the table. The electronic torch height control, motors and computer-aided manufacturing software are all managed within this single operating system that keeps the entire communication loop enclosed and it is delivered through a single visual display.

The new Visual Machine Designer (VMD) is the human-machine interface (HMI) of all Accumove CNC controllers as its user-friendly design and appealing layout is extremely easy to learn and use. This is credit to a set of new functions that have been installed directly in the controller to simplify the cutting process.

These features include Process Management that allows all parameters to be controlled through the 20in touchscreen display with a host of functions that can increase productivity. This intelligent system can automatically determine cutting conditions based on a few simple parameters entered by the user such as material thickness and type.

Additional innovations include plate alignment that simplifies material loading and calculates alignment to adjust and control trajectory accordingly and the laser positioning mode that simplifies the aligning of sheets.

The package also includes an automatic nesting module that enables users to load DXF or DWG files, enter the quantity and the VMD software will automatically generate the production nests.

Suitable for installation in any environment, the water table makes it possible to capture any dust released during cutting and any residual gas escape will remain below the exposure limit values for workshop conditions.