Latest laser technology developments from

GF Machining Solutions include the introduction of a new innovative laser texturing machine and, through its partnership with Swiss-based specialist machine tool manufacturer,

Crevoisier SA, a new high-productivity automated laser manufacturing cell.

GF Machining Solutions specialises in EDM, three- and five-axis milling, additive manufacturing (AM) and laser ablation machine tool manufacturing, as well as automation and tooling systems solutions.

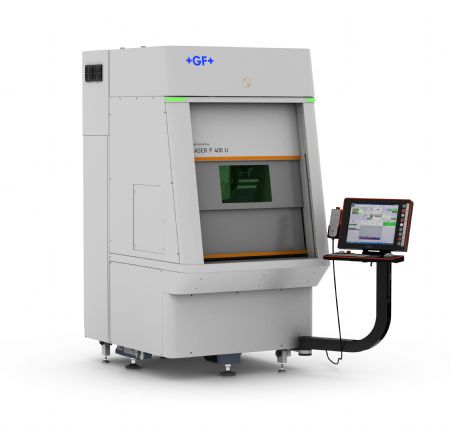

The new AgieCharmilles LASER P 400U Femto Flexipulse is designed for aesthetic and functional laser texturing and features a laser source that enables two different wavelengths to be used, making it possible to machine complex parts exploiting the machine’s three- or five-axis capabilities.

The machine delivers high accuracy and repeatable results and is primarily aimed at customers operating in the watch, jewellery, mould-making and cutting tool industries, as well as other sectors where micro-machined components are required.

It is the first machine combining the use of a femtosecond laser with five-axis texturing capability. The texturing operation delivers completely burr free results and eliminates the need for post-treatment and secondary operations. The green wavelength, with its reduced spot size, is ideal for use with or on reflective materials such as copper, gold and nickel.

The machine’s modular design includes an integrated bi-laser solution that combines two laser beams for texturing and engraving the same surface.

Moreover, the versatility of the laser head enables manufacturers to switch, quickly and seamlessly from one beam to the other, helping to significantly reduce production processing times, and increasing the machine’s application potential to machine a multitude of materials from aluminium and steel through to graphite, glass, sapphires and polymers.

Meanwhile, the latest version of GF Machining Solutions' GF Laser machine software brings additional intelligence and reliability to the laser texturing process.

The company’s much-vaunted ‘Smartpatch’ technology improves texturing quality and process productivity, and the innovative 3-D Map software allows the import and use of any 3-D computer-aided design (CAD) for the seemingly unlimited reproduction of textures, forms and shapes.

With more than four million parameter combinations, the machine pushes the boundaries for the laser machining of materials such as metals, ceramics, polymers, glass. With its user-friendly interface, the modification of the machining parameters including power, pulse sequences, wavelengths and frequencies, are quickly achieved and increase the machine’s appeal and application potential.

It is also the centrepiece of an automated manufacturing cell developed by GF Machining Solutions in partnership with Crevoisier SA - the Swiss-based automation, polishing and grinding machine tool manufacturer.

To meet the growing requirements from manufacturers to improve their productivity, flexibility and efficiency - both companies have combined their collective machine tool and automation expertise to create an automated loading cell specifically designed for GF Machining Solutions’ laser texturing machines.

In addition to the LASER P 400 U the cell includes a compact, versatile and high-speed C-66 robot which is controlled via a user-friendly touchscreen interface, featuring a flexible palletising system, a double gripper and a part alignment and turnover station. Loading times from robot to machine very are quick - typically less than 10sec.