Birmingham-based

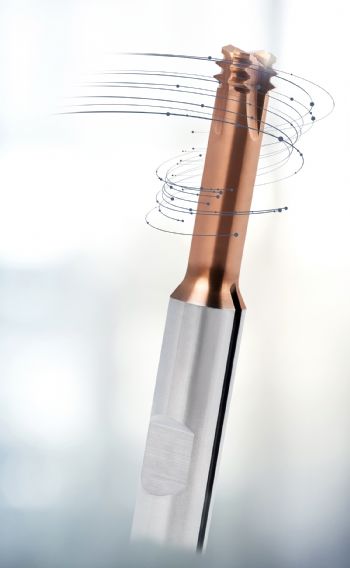

Guhring Ltd, has expanded it range of thread mills with the addition of the MTMH3-Z Drifter helical drilling thread mill which the company says delivers an impressive performance when processing materials up to 66HRc.

Combining core drilling and threading in a single operation, the MTMH3-Z provides excellent machining results and process reliability when wet or dry cutting all material types.

With two oil grooves on the shaft to provide optimum cooling with cutting fluid or air, the range also has a left-hand cutting geometry that stabilises performance during climb milling and this is complemented by the fine-grain high-performance carbide composition, which is characterised by its high hardness and is optimally suited for hard machining.

Supplementing this is Guhring’s special temperature resistant TiSiN coating that prolongs tool life and performance while making wet, as well as dry machining possible.

Furthermore, the MTMH3-Z Drifter incorporates a special face geometry with hollow grinding and this generates process-safe core hole drilling and thread milling possible in almost all material types.

With a shank diameter from 3 to 12mm and a neck relief from 5 to 40mm, the new thread milling series is suitable for creating threads from M2 to M16 on a material range that includes all steels and stainless, duplex, cast and graphite iron, aluminium and Ti alloys.

Suitable for drilling and threading holes up to 2.5xD in a single operation, the MTMH3-Z Drifter can drastically reduce set-ups, cycle times, tool inventory and costs for end-users. To simplify the process further, Guhring has also developed its CNC Guhro Thread Mill software that is free to download for Guhring customers.

This innovative software enables users to specify the thread data by selecting from all current thread standards and then inputting the material to be machined. At this stage, the software provides the optimal parameters.

The CNC Guhro Thread Mill software also allows users to record the CNC data according to their required milling strategies and parameters. From here, users receive their desired CNC programming code and datasheets.

The user simply has to import the programming data that is automatically recognised in CNC controls such as the Siemens Sinumerik, Heidenhain, Fanuc, Philips, Mazatrol or Hurco.