Belfast-based

Crossen Engineering, a leading specialist in both toolmaking and parts production for injection moulding, as well as pressing and stamping operations, has invested in a new Sodick AD35L spark-erosion machine from Warwick-based

Sodi-Tech EDM. The machine, which arrived in December 2020, is already busy producing mould and press tools for a range of important medical projects.

Founded in 1978, Crossen Engineering is today a full service provider, offering everything from component design and prototyping, to complete production. Despite operating a well-equipped toolroom and production shop, an upturn in medical work over the past 12 months saw the BS EN ISO9001 accredited manufacturer begin the search for a new die-sink EDM. The company already had a modern Sodick wire EDM on site, but its ageing Sodick spark-erosion capacity was 15 years old.

Managing director Paul Crossen said: “Medical work has high demands in terms of accuracy, complexity and turnaround time, which we know from experience is ideally suited to the attributes of Sodick machines.

“Our new machine was always going to be a Sodick as we want consistency throughout the business in terms of learning and training.”

The medical sector is proving resilient for Crossen Engineering. Among current projects is the manufacture of aluminium prototype mould tools for colostomy draining solutions, walking aids to improve mobility among arthritis sufferers, and bespoke wheelchair parts for children with disabilities.

Mr Crossen continued: “Also, during the pandemic, the demand for PPE has been strong. For instance, we have already made three injection mould tools for face shields, producing the finished parts on site.

“We received an order near the beginning of the pandemic to supply 70,000 face shields a week to our local NHS facilities as part of the HeroShield project, which is still running, but on a reduced level. In addition, we have machined a prototype mould for another face covering solution, as well as mouldings for sanitising stations.”

The Sodick AD35L was an ex-demonstration model that arrived on site in Belfast within four weeks of placing the order. Mr Crossen added: “Since installation, the machine has been busy producing mainly medical moulds, both prototype and production in aluminium and tool steel. For instance, P20 tool steel was used for the mould that makes the mobility product. The level of surface finish we require, along with mould complexity, means the AD35L is a great solution.”

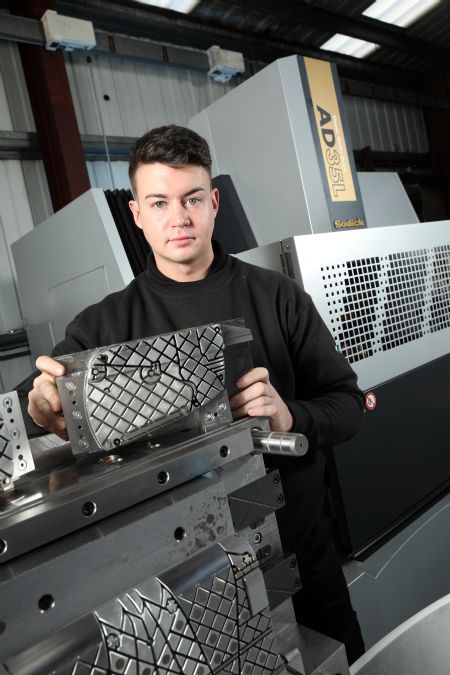

James Dunlop, Crossen Engineering toolmaker (pictured), said: “The new Sodick is 10-times faster than our 1995 die-sink machine, which may be a little exaggeration but it provides an idea of how EDM technology has advanced.”

The machine structure of the Sodick AD35L features optimised rib arrangements that increase rigidity by approximately 70%. As a result, deformation is minimised to allow optimum performance at high speed, supported by rapid-acceleration linear motors across the X, Y and Z travels of 350 x 250 x 270mm.

Crossen Engineering expects the new Sodick AD35L to attract new customers and orders, particularly involving high-end work and the company’s policy of continuous investment in the latest manufacturing technologies will ensure it remains at the forefront of its sector.

Mr Crossen said: “In Northern Ireland we are well aware of our competitors. However, we differentiate from others by designing and manufacturing all tooling on site, as well as offering the capability to undertake both small-batch and high-batch production runs, be it injection moulding or pressing.

“In short, we are a single-source solution, from concept to production. We can respond to short lead-time requests and like to make sure that bringing a new product to market is painless.”

Crossen Engineering offers injection-moulding capacity from 30 to 550 tonnes, for parts ranging in weight from 1 to 2.5kg. The AD35L is capable of creating tools for the largest moulding machine on site, which was an important factor in its selection. The machine also finds use producing press-tool parts. Crossen can provide up to 500 tonnes capacity for metal stamping, the highest in Northern Ireland.

Mr Crossen concluded: “As well as the medical industry, our regular client base is also picking up and as we look ahead, the order book looks fairly robust, although there is still capacity to take on more.

“Demonstrating our flexibility and adaptability, we have customers in sectors that include automotive, aerospace, household appliance, leisure, construction, marine, materials handling, electrical, and food and drink.

“Our service is modular in that you can take from it what you need, when you need it, as a stand-alone service or as a complete design and engineering solution.”