Machining parts to precise specifications with no room for mistakes is imperative when manufacturing racing cars. It was therefore no surprise that Cambridgeshire-based

CTR Developments, which is heavily involved with Tier One manufacturers, sought out a CAM system that would enable it to achieve the highest levels of precision and machining quality, together with short lead times.

As a result, the company chose iMachining technology from Barnsley-based

SolidCAM UK Ltd, a decision made easier by the fact that CTR Developments had been using SolidWorks CAD system for some 15 years.

Therefore, investing in a CAM solution that ran directly within CTR’s existing CAD system provided seamless integration and full tool-path associativity, with an extremely short learning curve due to the familiar environment.

Matthew Chamberlain, CTR’s company secretary, said: “I am not a machinist and have never been formally trained, but I wanted to take control over the bits and pieces we were sending out to be manufactured.

“The one-button-click calculation of 3-D roughing cutting paths was a revelation. Moreover, the surface finish we get with 2-D finishing passes when using iMachining is better than anything we were able to achieve previously.”

“Although iMachining can help ‘companies to save 70% and more in machining time’, it was not this that attracted CTR to purchase this CAM software; the motorsport company’s main focus is quality.”

Dr Chamberlain added: “We don’t run our machine hard and do not focus on time savings, but tool life is important and I know that iMachining has also prevented a number of collisions.

“That said, being able to cut machining time means we can get a prototype to customers before they commit to costly tooling, so although not at the forefront of importance, time savings are still a key factor.”

Avoiding downtimeHe continued: “The patented iMachining technology avoids machine downtime, as it ensures there is less wear and tear on our CNC machines, resulting in higher machine up time, reduced machine maintenance costs and extended machine life.

“By allowing a full depth-of-cut to be used ensures that the entire length of the tool is used, not just the bottom part, resulting in the average tool-life being increased by a factor of five or more.

“Furthermore, iMachining has enabled us to eliminate the need for special tooling when machining hard materials, although much of our machining is based on aluminium 7075 T6, which has zinc as the primary alloying element; it offers excellent mechanical properties and exhibits good ductility, high strength and toughness, as well as good resistance to fatigue. We use this material for parts such as suspension uprights and steering wheels.”

CTR has experience in most classes of motorsport, including F1, and the company can produce anything from a sump tank to a complete chassis.

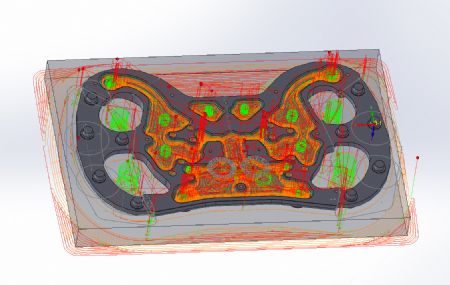

Furthermore, Dr Chamberlain says using iMachining means they benefit from ‘zero air cuts’ when machining, as tool-paths are driven by a “dynamically updated 3-D model of stock, which is precisely updated after each short segment of tool movement.

“In addition, iMachining’s Technology Wizard, automatically generates optimal feeds and speeds, eliminating trial and error to find the optimal machine settings, thereby keeping the tool at maximum efficiency.

“We don’t have to specify any feeds or speeds, the software just calculates it, taking away the risk of human error.”