Following the launch of two new carbide turning grades in October 2020,

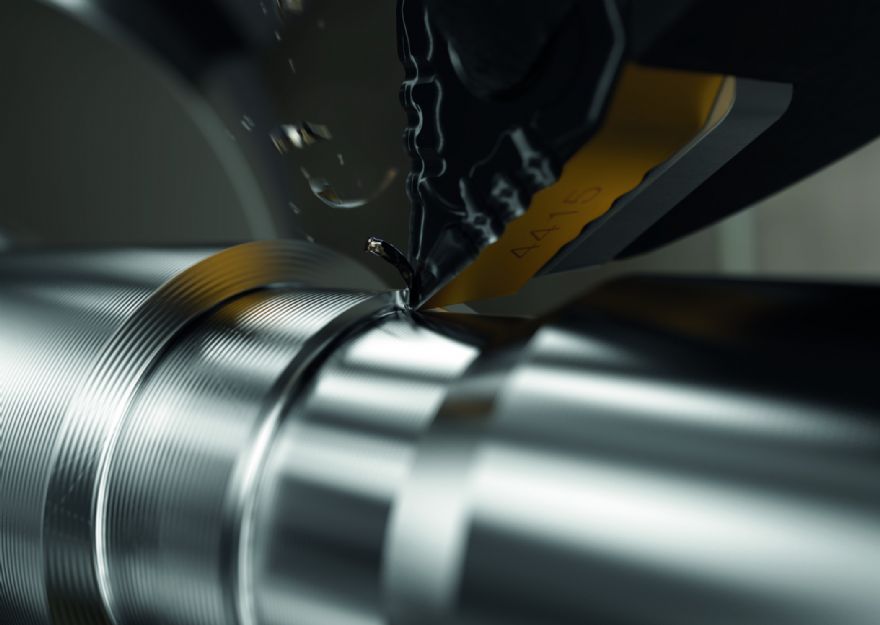

Sandvik Coromant has now extended its steel turning product line. The latest insert grades, GC4415 and GC4425, are designed for external and internal machining of low-alloyed and unalloyed steels.

They are considered ideal for manufacturers operating in mass and batch production set ups. GC4425 is a machinist’s first choice for steel turning, outperforming competition in a majority of steel turning applications. as it provides improved wear resistance, heat resistance and toughness, considerably expanding the application range. Grade GC4415 complements GC4425 where even more heat resistance is required.

To increase their use for steel turning applications across the automotive, energy and general engineering sectors, the upgrade includes more insert shapes for each grade. Having access to the correct insert shape is vital for effective finishing and roughing operations, and the insert shape should be selected relative to the entering angle accessibility required of the tool.

Product innovationsRolf Olofsson, Sandvik Coromant product manager, said: “In October 2020, Sandvik Coromant made a total of 547 items available as part of the grades’ release. However, to meet the demands of our wide-ranging customer base, we always aim to build on our product innovations and continuously improve. As a result, an additional 381 items have been added to the range.

“The GC4415 and GC4425 inserts show superior wear resistance over competing inserts, which contributes towards extended tool life and predictable performance with every use. This also minimises material waste, both from the workpiece and the insert.

“With these benefits in mind, offering extra insert shapes that are compatible with more tool holders means that more customers will be able the take advantage of GC4415 and GC4425 for their steel turning operations.”

While still relatively new to the market, GC4415 and GC4425 have demonstrated measurable productivity benefits since their first release. One general engineering customer, using the GC4415 insert to carry out roughing on a P2.5.Z.HT steel workpiece to machine a pulling rail, saw a 80% productivity increase and a 100% increase in tool life when compared to a competing grade.

Elsewhere, when roughing an axis for a power generation customer, the GC4425 demonstrated a 90% increase in tool life, providing secure machining with stable and predictable flank wear and no notch wear.

Mr Olofsson concluded: “Despite launching at the end of 2020, GC4415 and GC4425 have already delivered huge productivity and cost-saving benefits for our customers. Every manufacturer wants to achieve increased metal removal rates, more pieces per edge, reduced cycle times, minimised waste and optimised inventory use. For the GC4415 and GC4425, the proof is in the numbers.

“Now, with the latest upgrades to the insert range, Sandvik Coromant will be able to help even more customers enjoy the benefits of optimised, efficient steel turning.”

To learn more about the GC4415 and GC4425 grades for steel turning operations, and to book a consultation with a Sandvik Coromant expert, visit the website (

www.sandvik.coromant.com).