Hyundia WIA

Hyundia WIA is utilising

ModuleWorks CNC software technology to enhance its ‘smart factory’ concept. Integrated in the Hyundia WIAiTROL smart machining platform, the ModuleWorks technology furthers the machine tool manufacturer’s vision of intelligent machining systems that offer enhanced monitoring, efficiency and protection as well as safe, cost-efficient operator training.

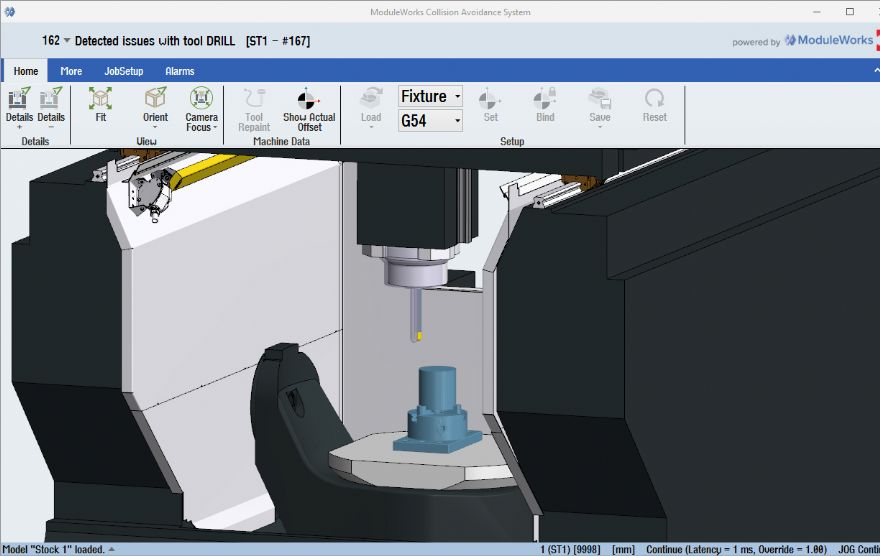

To protect machines from damage that can occur due to operating and programming errors, Hyundia WIA uses the ModuleWorks Collision Avoidance System integrated on the Siemens Sinumerik 840D SL CNC control.

The ModuleWorks CAS runs in real-time during the machining process and uses the same motion data as the real servos to provide a highly accurate graphical simulation of the machine kinematics. Intelligent look-ahead algorithms detect potential collisions, in auto or jog mode, and alert the operator to stop the machine before a real collision occurs.

The Siemens control allows remote access which means data from the ModuleWorks CAS is potentially available to the Hyundia WIA HW-MMS superordinate monitoring system that enables engineers to monitor machine safety and performance at any time and from anywhere.

The ModuleWorks Visual Twin extends the smart factory concept further to incorporate operator training. Under the motto “as real as it gets”, the Visual Twin combines industry proven ModuleWorks simulation technology with ‘state of the art’ computer animation to deliver an authentic experience that enables operators to train on a specific machine in a fully virtual environment, thereby eliminating expensive downtime, waste material and any risk of damage to the real machine.

Jae-Yong Ha, head of Machine Tool R&D Center at Hyundai WIA, said: “Our goal is to deliver intelligent, integrated machining solutions that enable our customers to transition to industry 4.0 manufacturing. The ModuleWorks CAS and Visual Twin take us closer to this goal by offering enhanced machining safety and optimised productivity that fits perfectly into our smart factory concept.”

Hyundai WIA demonstrated the iTROL smart factory platform with integrated ModuleWorks CAS on the Hyundai WIA XF6500 machining centre at an Open House event at its European headquarters in Rüsselsheim, Germany, last year. The platform with integrated ModuleWorks Visual Twin is now planned for demonstration during the

HINEX 2021 (Hyundai Wia International Machine Tool Exhibition) at the HYUNDAI WIA headquarters in South Korea taking place 8 to 10 September 2021.