DMG Mori

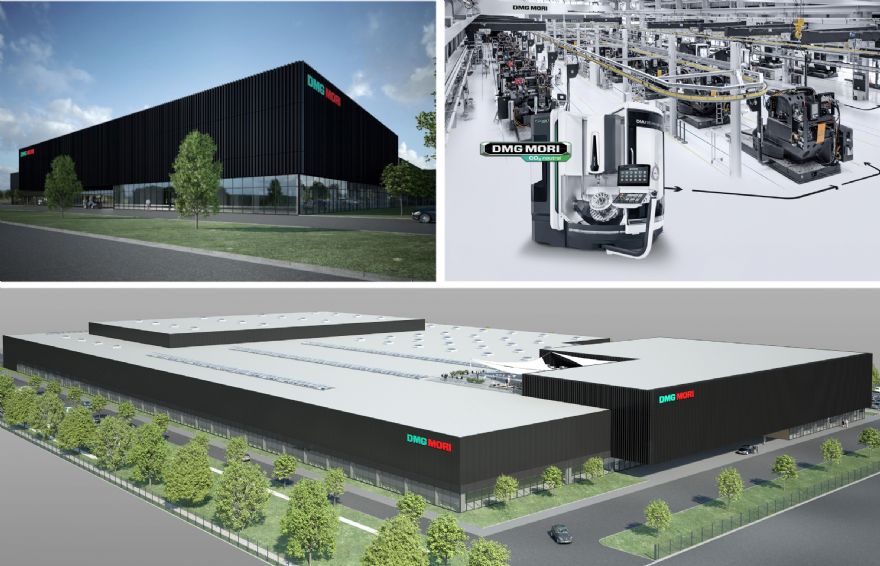

DMG Mori has unveiled plans to construct a 35,000m

2, highly automated, digitalised production plant to produce DMU series five-axis milling machines in Pinghu, near Shanghai, which is scheduled to open by the end of 2022.

Christian Thönes, chairman of the executive board of DMG Mori Aktiengesellschaft, said: “We are building the world’s most modern production plant in Pinghu for 75 million euros and are showing the full potential of our holistic technology solutions: flexible automation, end-to-end digitalisation, cutting-edge flow assembly with automated guided vehicles (AGVs) for five-axis milling machines.”

With the goal to promote the machines as ‘Made in China – for China’, the ‘state of the art’ production facility is designed to produce 2,200 machines each year. The new site covers a total area of 70,000m

2.

Pinghu is located in the middle of the Yangtze River Delta – one of the most dynamic economic zones in China – and has developed rapidly in terms of economy and technology due to its geographical advantages.

In September last year, DMG Mori put into operation the new monoBLOCK Excellence Factory in Pfronten, Germany, with 36 AGV transport systems. The value chain powered by the "no-code" platform TULIP, which is developed and completely digitalised by the company’s own employees, will now also be used in China.

The high demand for machine tools in this fast-growing market is currently serviced by more than 500 people. In addition to the technology centre in Shanghai and production plant in Tianjin, there are eight sales and service companies (Beijing, Shenyang, Chongqing, Xi'an, Shanghai, Ningbo, Suzhou, Shenzhen).