Wiltshire-based

Rotron Power Ltd, a specialist designer and manufacturer of innovative rotary engines, has purchased an advanced

pl Lehmann CNC rotary table to support its machining activities.

Established in 2008 in Semley, Rotron has grown rapidly to become a major force in the supply of rotary engines for Unmanned Aerial Vehicles (UAVs) and increasingly for other applications. When compared to traditional rotary power plants, the efficient fuel-burn characteristics of Rotron’s, high power density, low weight engines, provide impressive endurance lifecycles and increased range capabilities.

The cutting-edge R&D work that has resulted in Rotron’s global success within the UAV sector has enabled further aviation applications to be exploited. For example, the company has developed VTOL, an unmanned Quadcopter lift platform designed for transporting a variety of payloads, also SKYQUAD, a flying car that is equally at home in the air or on the ground.

Recent non-aviation projects include a high performance, multi-fuel marine outboard rotary engine and a bespoke two stroke engine for a powered surfboard. The latest application for the company’s advanced rotary engine technology is an innovative racing motorcycle which produces 204hp and weighs less than 130kg.

In addition to developing the company’s own proprietary technologies, Rotron acts as an advanced design and analysis engineering consultancy to a wide range of international businesses. Along with other services, the company provides concept development, engineering, prototyping and production management.

As Rotron’s consultancy contracts specify that staged payments are made by clients on the completion of specified design and development steps, the time taken to arrive at these ‘milestones’ is extremely important. Some of these payments are made on the presentation of prototypes and of fully operational products.

Therefore, in addition to the efficient manufacture of Rotron’s own products, the speed and flexibility of the company’s machining activities is vital to the commercial success of the its consultancy operations.

Rotron’s cutting-edge production capabilities are supported by the employment of skilled staff and by the use of a wide range of highly efficient CNC machines supplied by Burlescombe-based

XYZ Machine Tools.

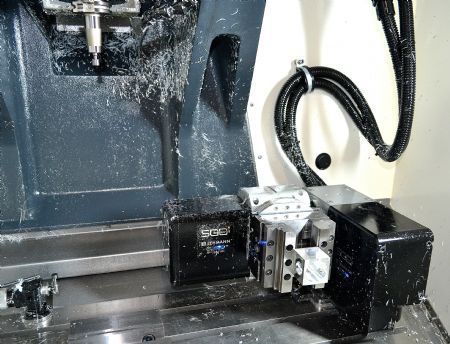

To enable further machining efficiencies to be gained the purchase of a CNC rotary table was recently considered. Following a conversation with XYZ, a decision was made to purchase an advanced Lehmann T1-510520 model.

Rotron production manager Sam Bellefontaine said: “As we need to efficiently machine parts with demanding levels of precision, we have invested in a range of cutting-edge XYZ machine tools which have enabled us to develop an extremely efficient manufacturing operation and over several years we have received excellent training and outstanding technical support from the company.

Therefore, when the need occurred to purchase a rotary table, we were happy to take advice from XYZ’s technical staff and to invest in a Lehmann T1-510520 unit.

“The installation and interface help we received from XYZ and from Paul Tolin, pL Lehmann’s local service agent based in Rugby, helped to put the T1-510520 into use and enabled us to gain maximum benefit from it. The machining flexibility and speed that it has delivered is now proving invaluable.

“Given the complex nature of many of the parts we manufacture, before using our rotary table we would need to perform two or three different machining operations on them. Now, thanks to the ‘all-round’ machining capability delivered by our Lehmann rotary table we can complete the same machining work in a single hit.

In addition, we no longer have problems related to the accurate relocation of workpieces for secondary machining operations. These factors have helped us to maintain our high precision standards and to slash the machining times of many of our components.

“The relatively small footprint of our Lehmann’s rotary table means that, when it is mounted inside our XYZ machine tool it occupies a minimum area of its bed. As well as leaving room for the fitting of additional work-holding on the machine’s bed, the compact size of the rotary table means that even when it is not required, we can leave it inside the machine while other milling and drilling work is being performed.

“Also, when we are not using it, the rotary table’s low profile helps to increase the available working volumes of the machine.”

Throughout the world production costs are constantly under pressure, therefore companies are continually searching for rapid, lean manufacturing solutions. Increasingly, the use of advanced CNC rotary tables is being seen as a way of achieving highly efficient machining.

For example, as it is estimated that 90% of all machining tasks performed by five-axis machining centres are basic five-sided procedures, rather than purchase an expensive five-axis machining tool, the fitting of a rotary table to a company’s existing three-axis vertical machining centre represents a cost-effective, technically capable alternative means of achieving highly effective 3+2 axis capabilities.

As a CNC rotary table costs a fraction of the price of a five-axis machining centre, the use of this flexible machining aid is being embraced by an increasing number of manufacturers. Following the fitting of a CNC rotary table, users report that their enhanced capabilities, reduced machining times and increased outputs results rapid returns on their investments.

CNC rotary tables supplied by pL Lehmann are available in four sizes — 507, 510, 520 and 530mm with centre heights from 110 to 240mm. Thanks to the company’s innovative modular design approach, from these four basic size options it is possible to create over 170 different rotary table variants — from basic single-spindle fourth-axis units to four-spindle tilting rotary tables with fourth- and fifth-axis capabilities.

Therefore, rather than purchase a ‘nearest-fit’ option, pL Lehmann’s customer focussed approach ensures that each purchaser receives a high-quality CNC rotary table that exactly matches their specific needs.

In addition to solving todays machining challenges, the company’s modular design system means that the purchase of a well-engineered Lehmann CNC rotary tables represents a safe, future-proofed investment.

For example, if customers’ requirements change, rather than invest in a new rotary table, their existing Lehmann units can be easily amended to accommodate any changes of use.

Lehmann’s standardised spindle arrangement allows the use of an extremely wide range of workpiece clamping systems. As a result, in addition to standard work-holding being set-up for an initial workpiece range, the system can be quickly converted to accommodate other workpieces.

Lehmann’s heavy duty CNC rotary tables have earned a global reputation for their outstanding performance, quality and longevity. Further aiding efficient, precision machining, the company’s robust products benefit from excellent clamping torque, load weight capabilities and accuracy specifications.