The European Space Agency’s Rosalind Franklin Rover is due to launch from Kazakhstan next summer (2022), and is scheduled to land on the surface of Mars in March 2023 to join the Perseverance Rover in the exploration of the Red Planet.

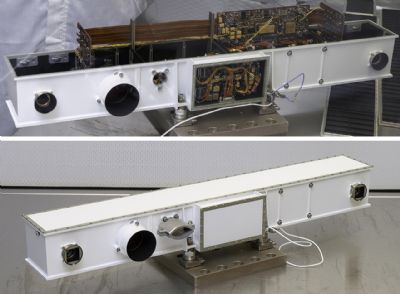

On arrival, it will be tasked with identifying signs of water-rich minerals, that could indicate the possibility that life once existed on Mars. Key to these investigations will be the Optical Bench — ‘the eyes of the rover — containing two stereo cameras, a mono high-definition camera and array of electronics. Known as the ‘Pan Cam’ this device was developed and manufactured in Surrey by the Mullard Space Science Laboratory, the largest university space research group, and part of the Department of Space and Climate Physics at University College London.

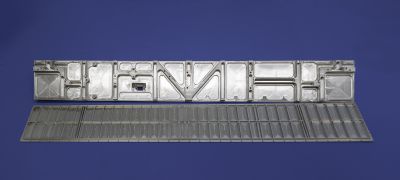

The optical bench comprises a box with separate top and bottom, machined from 5083 grade aluminium, that are joined together using electron beam welding techniques. Machining was completed in the laboratory’s workshop in Dorking using the smallest vertical machining centre available from Devon-based

XYZ Machine Tools .

Due to the complex design, there are some extremely fine details to machine, such as an O-ring groove around the lid, measuring just 0.35mm wide, as well as numerous M1.6 threaded holes, which were thread-milled using the latest tooling available from Sheffield-based

Ceratizit UK & Ireland Ltd.

The other challenge was that the parts had to be machined from billet material, with the machine and tooling having some extremely thin wall thicknesses to contend with.

While the initial thought process may have been to use CAD/CAM to generate the programs for these complicated parts, with their numerous pockets and features; the decision was taken to program directly at the machine using the ShopMill software within the Siemens control.

Simon Hemsley, head of mechanical workshop, said: “Due to the low volume (only a few prototypes and the final finished parts were required), it was easier to program at the machine, as the control makes it so easy to finesse the toolpath and achieve the fine details that might not have been possible using an automated CAD/CAM program.”

Another key element of programming at the machine is the ability to adjust the step-over distance when milling. The default amount is set at 45%, but due to a requirement to achieve finer finishes, and not having any great restriction on cycle time, this was adjusted to 2%.

Mechanical engineer Adrian White added: “Reducing the step over to 2% and using a 3mm ball nose cutter greatly improved surface finish. The obvious compromise was cycle time, with some parts taking 40hr to machine complete from billet material.

“However, this extended cycle time was not an issue, as not being a production environment, pressure to finish parts is not the same. Prior to having the tool-change facility provided by the XYZ machining centre, we were restricted to bed mill type machines and extended running would not be possible. The benefit of the tool changer was a game changer for us, allowing us to run lights out.”

The success of this project convinced Simon Hemsley and his team of the value and flexibility provided by machining centres with tool change, so much so that an order has just been placed for an XYZ 500 LR linear rail vertical machining centre.

This machine, which has been part-funded through the Government’s Research Capital Investment Fund, comes with the latest Siemens 828D control with the optional advanced programming software package that includes the Shopmill technology.

This along with the MiniMill will ensure at-machine programming continues for the foreseeable future as the exploration of the solar system continues apace.