Now available from Tamworth-based

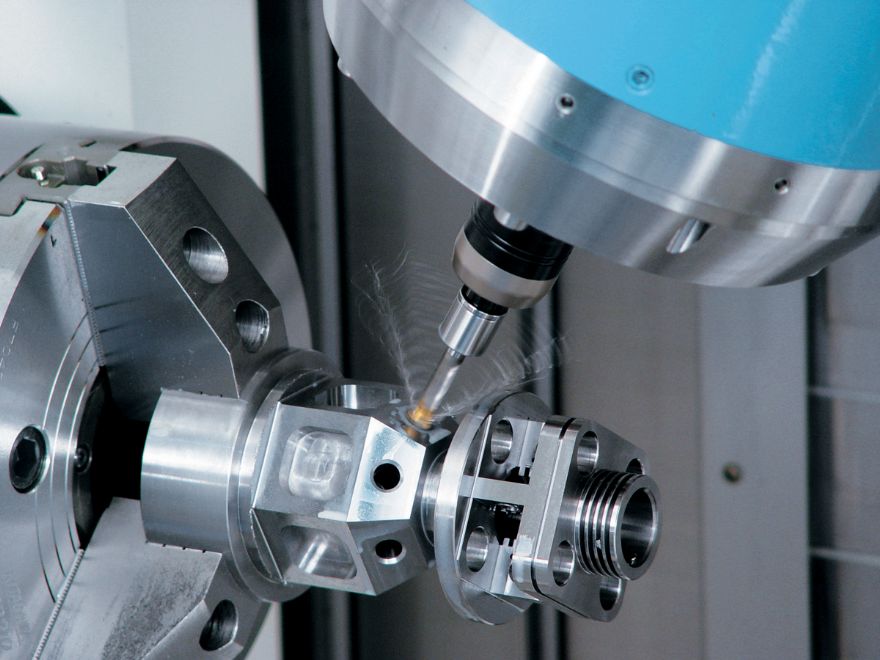

Industrial Tooling Corporation (ITC) is the innovative Mega Synchro tapping chuck from BIG Kaiser which features a special built-in function to compensate for synchronisation errors that may occur during rigid tapping.

The comprehensive product line incorporates more than 60 body types and 193 tap holders and the diverse portfolio enables the end user to select the perfect combination between the fixture and the tap holder, providing the ideal cantilever length for any machine and processing situation.

While there are a multitude of tapping systems available, synchronisation errors often remain during tapping. A small gap is caused by timing during the change between forward and reverse rotation of the spindle and the feed direction from minus to plus.

In addition, distance tolerances on the tap also cause errors. Depending on the shape, some taps also have a stronger cutting resistance that creates another anomaly.

The Mega Synchro tapping chuck compensates for synchronisation errors with any type of tap as the system minimises thrust load to both the tap and workpiece, improving thread quality and extending tap life.

The chuck incorporates a unique feature that intercepts the tap-to-spindle distance when using a tapping cycle to reduce cutting forces. This is complemented by a body and tap holder that are fixed with a drive key in the rotation direction as well as the square of the tap to guarantee stability and process security which is further improved by the coolant system that delivers coolant through the tool as well as around the periphery of the tool simultaneously.

ITC’s business development manager Andy Boyles said: “There are many companies now producing ‘Synchro’ type tapping heads, but the BIG Kaiser Mega Synchro tapping head is unique. Due to its design, it is possible to interchange the tap holders to different sizes, and it is available in several different lengths.

“Furthermore, the system permits through-coolant synchro tapping in very deep holes with a very stable set up. It is also extremely cost-effective when compared to an ER collet-type synchro tapping head.

“Synchro tapping heads reduce the load applied to the tap at the reversal of the spindle, this improves thread quality and increases tool life.

“Like anything we sell at ITC, we are always keen to prove the capabilities of the system to the customer with a no-obligation trial.”