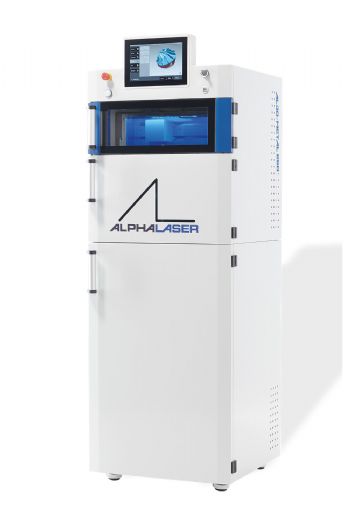

The latest laser-based technology to become available from Bromsgrove-based

TLM Laser is the new AL-3D Metal 200 additive manufacturing (AM) system which brings a new dimension to metal AM through the use of a cartridge-based closed powder circuit.

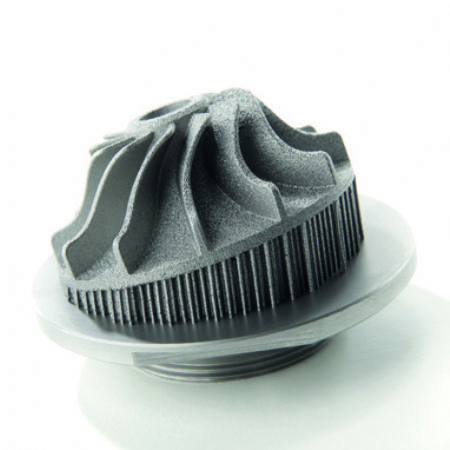

The ability to manufacture high-precision components with impressive quality standards combined with unparalleled freedom, in terms of design and geometry, are just a few of the reasons behind the rapid growth of 3-D printing. The AM process also saves material and resources, by building a component layer-by-layer as opposed to having it machined from solid.

The new AL3D-METAL 200 3-D printer encompasses all of these properties and is characterised by its safe, clean and economic powder handling concept. The cartridge-based closed powder circuit enhances safe working practices as the operator doesn’t come into contact with the powder at any point throughout the entire 3-D printing process.

Specially developed for the precision mechanical, medical technology, dental and jewellery industries as well as research and development laboratories, this compact 3-D printer offers optimum detail accuracy, precision and maximum safety in handling both the laser and the metal powder.

A further characteristic of this system is the ability to produce layers of different material within the same component. This is achieved by stopping the print, changing the material cartridge and then re-starting the printing process.

(The intelligent cartridge concept not only provides an innovative solution to powder handling, but allows different materials to be layered within the same component)

The AL3D-CARTRIDE is an intelligent plug and play cartridge based system which allows fast offline preparation of materials, and the cartridge containing the metal powder is simply loaded and located within the system ready for use. At the end of the build process, the component and unused powder remain captive within the cartridge which can then be transferred to a separate unpacking station.

The cartridge is inserted and located within the AL3D-CABIN – the unpacking station - in the same way as the 3D printer, allowing the operator to retrieve the sintered component and capture the residual power is a safe, ergonomic and efficient manner.

A 200 W CW, 1070nm fibre laser is at the heart of the system which delivers a 50μm spot size, and the system can be used with a variety of metals including: iron alloys, nickel-based alloys, cobalt-chrome alloys and precious metals.

Two variants of the system, the AL3D-METAL 200-50 and AL3D-METAL 200-100 offer 50 x 50mm and 100 x 60mm build volumes respectively. The system also boasts a compact footprint of just 600 x 600mm making it ideally suited to any working environment.

Andy Toms, director of TLM Laser, said: “This system is highly intuitive to use, you simply select a cartridge with the desired material, insert it into the printer, select the desired print file from the touch screen interface and start the printing process.”

This new 3-D metal printing technology is available from Bromsgrove based TLM Laser, Alpha Laser’s UK and Ireland distributors, and just part of a comprehensive and growing range of laser-based technologies and systems offered by the company.