The productivity of deep hole drilling has now taken a significant step forward with the arrival of a new series of gun drills from Birmingham-based

Guhring Ltd. The new VB 80 four-fluted deep hole drills with a solid carbide head and the solid carbide VB 100 Series is ideal for cast iron drilling.

The straight flute deep hole drills are very robust with a geometry that ensures the drill core is more than 50% of the overall diameter, demonstrating maximum rigidity, strength and performance.

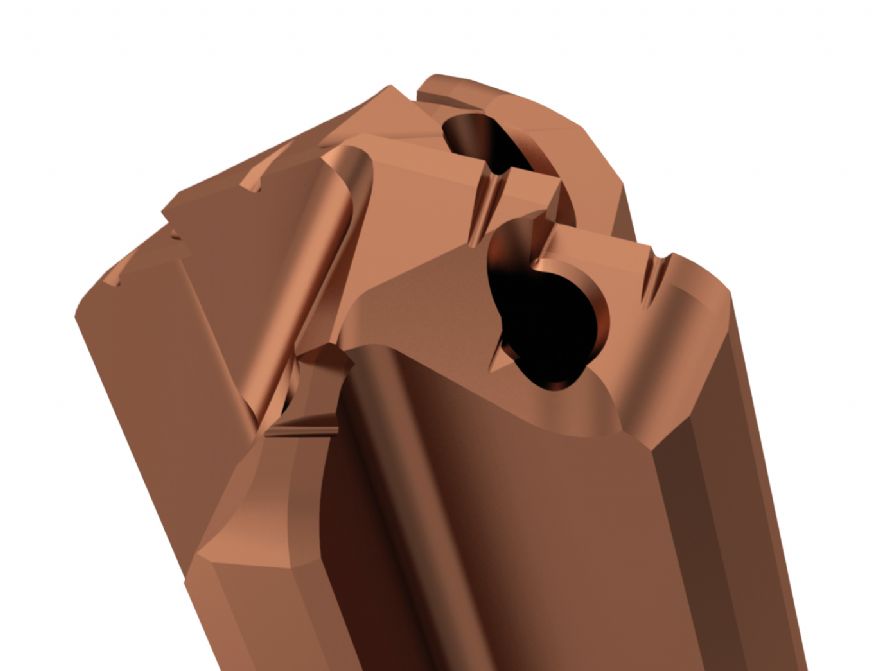

Guhring has also developed an innovative geometry that consists of two core cutting edges that are supported by four outer flutes that are axially displaced to split the chips, improve centring and precision while reducing cutting forces.

This means the bottom of the hole will be two-stepped, as the drill has a 141deg angle on the primary cutting edge, which is followed by a 145deg cutting angle on the outer cutting edges.

The chip clearance is further improved by four cooling channels that allow high-pressure coolant to be directed to each of the four cutting edges — prolonging tool life by preventing swarf re-cutting and creating an efficient chip removal sequence.

The new VB 80 and VB 100 deep hole drills also consist of four round margins with a 90deg division that further enhances precision, concentricity and surface finishes down to IT6. With the abrasive wear divided through four flutes as opposed to two, as in most ranges, the new VB 80 and VB 100 have proven to improve tool life and performance significantly.

In fact, the new deep hole drills have reduced cycle times by more than 30% during field tests while also extending tool life, hole quality and overall performance far beyond the realms of two-flute gun drill variants.

At present, the new VB 80 and VB 100 Series is available in diameters from 13.5 to 28mm diameter with flute lengths up to 500mm. Additional diameters and lengths can be specified upon request. The new drills can be reground from five to 10 times depending upon the axial wear on the drills.

This regrinding facility drastically reduces cutting tool costs for the end-user with the drills being returned in a perfect ‘as-new’ condition. At present, the VB 80 and VB 100 are new product lines and Guhring is currently developing an extended range of drill diameter and length options.