Birmingham-based

Cutting Blue Ltd was founded four years ago by Piotr Parobczy as a consultancy focused on the programming of complex high-value components for the Formula One and motor-sport industries.

However, in the last 18 months, the small sub-contract company has also been manufacturing, having bought machine tools from Doosan and DMG Mori that it is programming using hyperMill CAM software from Bicester-based

Open Mind Technologies UK Ltd.

Located in central Birmingham, Cutting Blue has rapidly built a customer base in the electric vehicle (EV) and micro-mobility sectors, manufacturing drivetrain components, battery and electronic enclosures. The company bought its large bed Doosan DNM6700 and DMG Mori CMX600V machining centre to undertake the processing of primarily plastic and aluminium parts that are machined in batches from 100- to 500-off.

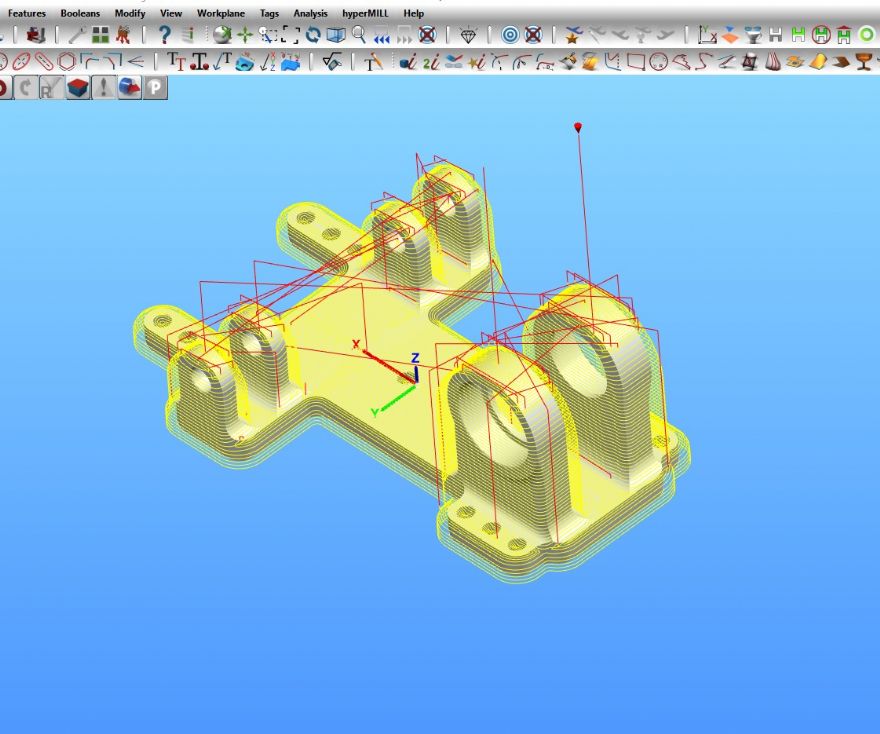

Explaining his use of hyperMill, Mr Parobcz said: “I have been using hyperMill as well as other CAM systems for more than 10 years; and while as a business we are currently only running three-axis machining centres, our consultancy division of the company undertakes the programming of complex components for a host of industry sectors. It is here that the benefits of hyperMill are evident.

“We have our system fully loaded with strategies from MAXX machining and five-axis through to tube machining, multi-blade machining, probing, turning and more. That is the beauty of hyperMill, you can add features to suit your specific requirements.”

Mr Parobcz says that while components machined at Cutting Blue often have cycle times ranging from five to 22hr per part, hyperMill generates considerable cycle time savings. He explained: “By using strategies like the MAXX machining for roughing, we can use high-performance cutting tools and trochoidal milling to reduce cycle times on some parts by more than 30%.

“Our CAM programming consultancy achieves equally impressive cycle time reductions for our clients. We have one customer that is five-axis machining impellers for the marine industry and we have yielded impressive cycle time reductions. By using the Multiblade feature in hyperMill, the blades are quite easy to programme, as the strategy has a host of small options that simplify the process while a lot of the other tasks are automated.

“The customer has reduced the cycle time from 1hr per impeller to just 20min. This is a credit to the combination of hyperMill strategies and the use of conical barrel tools that enable the tool-paths to run with a stepover of 3mm or more compared to just 0.2mm with conventional ball-nose tools.”