A machinist in the inspection room at Wilford at the end of a measuring cycle on a Nibron (high-strength cupronickel) component that he was previously responsible for loading onto the LK AlteraS 10.10.8 with the help of Launchpad

A machinist in the inspection room at Wilford at the end of a measuring cycle on a Nibron (high-strength cupronickel) component that he was previously responsible for loading onto the LK AlteraS 10.10.8 with the help of LaunchpadTwo coordinate measuring machines (CMMs) manufactured by

LK Metrology, Castle Donington, have largely superseded the use of a pair of smaller-capacity 15-year-old machines in the inspection room at the sub-contract machining specialists WLR Precision Engineering, which is based in Wilford, Nottinghamshire.

To enable production operators as well as quality inspectors to operate the new CMMs and easily access the measurement reports, the machines have been supplied with LK Launchpad — an icon-driven touch-screen operator menu — along with a network of viewing screens and tablets.

The simplified operator menu lists, all the available inspection programs and the exact position the part should be placed on the machine table for inspection are available with ‘just a few clicks’ — giving operators the confidence to perform measurement tasks, while greatly enhancing flexibility and opening up the system for use by non-specialist CMM operators. Measured results and automatically generated reports may be shared between screens, tablets and other networked devices for easy access and viewing from any location.

WLR offers an ‘all-encompassing service’, and for almost all contracts the company manages the entire production process; a proportion of the value of each part is rigorous metrology, often involving 100% inspection. Contracts are received mainly from the oil and gas, pharmaceutical, medical, laboratory and scientific instrumentation industries.

Tom Parr, WLR’s sales manager, said: “The increasing confidence that our customers have in the accuracy and consistency of components they receive from us has resulted in our winning considerably more business in virtually every sector that we serve.”

Helping raise that level of confidence was the purchase in 2015 of the first LK CMM, an AlteraS 15.10.8 with a measuring volume of 1,524 x 1,016 x 813mm. The purchase of this machine, which quickly transformed quality control activities in the Wilford factory, was triggered by a steep increase in components ordered by key customers coupled with a requirement for more comprehensive 100% inspection and detailed reporting, as well as defence sector requirements for traceable measurements and certified reports covering the supply of matched components.

Large table areaA major benefit of this CMM is its large table area — about 1.0 x 1.5m — which can accept up to 12 identical components at a time for batch inspection, instead of just one as on either of the older CMMs. Typically, five batches can be inspected during a day shift with a load time of about 5min between each batch.

After components have been placed in-situ, every part is measured in a single, automatic cycle, the longest of which is 2hr. The person is free to work elsewhere on other metrology equipment for most of the day, with the time the inspection will take known exactly; previously, an inspector was committed to sitting by a CMM all day, loading each part individually prior to every automatic measurement cycle.

With the previous metrology route, subsequently preparing reports by hand on 12 inspected parts would typically take 3hr; now, big savings are achieved due to the ability of LK’s CAMIO CMM software to perform the task automatically.

A comprehensive, graphically supported inspection report is generated on an entire batch in a matter of minutes, covering perhaps 30-40 critical dimensions on each part — complete with colour-coded content in the event of any non-conformance. The report data is exported directly into an Excel spreadsheet.

All these advantages allowed WLR to accommodate a surge in orders from several customers. However, by May 2021, a further increase in batch-measuring capacity was needed, as was in-process inspection of a particular family of components for one customer.

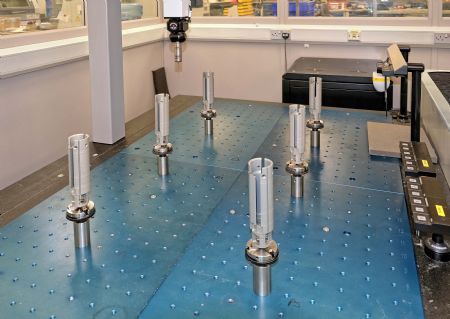

This time a smaller LK AlteraS 10.10.8 with a working volume of 1,016 x 1,016 x 813mm was purchased, together with the latest CAMIO 2021 software and LK’s Launchpad software; the latter enables not only the two WLR quality inspectors and quality manager Tony Blood to load parts singly or in batches of up to six at a time, but also the 10 day-shift and 5 night-shift machine operators to do the same.

Launchpad makes it simple to load the correct program for inspecting a component, which is easily identified from stored data, with details called up via simple graphical menus and icons on a screen positioned by the machine. The operator can locate the component by selecting: the customer by name; part category; or by directly calling up the part itself — complete with details of the machining process.

Set up on the CMM is straightforward, assisted by 12mm-thick aluminium fixture plates — pre-drilled with a grid of holes at a 50mm pitch — fitted across the granite table of the machine. The operator simply places the component in a numbered location on one of the fixture plates, as indicated by the Launchpad graphic, and instigates the measuring program by pressing a button on the touch-screen.

Moreover, the same inspection results that appear on the screen adjacent to the machine are also available on networked tablets used by machinists on the shopfloor — and the information can be shared with other devices. WLR says these capabilities create an environment where machinists become ‘invested in the procedure’, adding that the next step will be to include a function that allows operators to be alerted via their tablet when the measuring cycle is complete, so there will be no need for the person to keep an eye on the time.

CAD-based programmingPre-drilled location plates are also a feature of the larger LK CMM, as is the ability to program the machines directly from CAD. Before the new LK CMMs arrived, it was sometimes necessary to produce a first-off component for a customer in up to six operations on a succession of machine tools, then take the part repeatedly to the inspection department to be measured and subsequently corrected if necessary.

After it had been finish-machined, the component was used as the basis for teaching a measuring program into one of the older CMMs. Now, in the same way that a metal-cutting program is derived directly by a CAD/CAM system from an electronic model of a customer’s component, the DMIS inspection cycle for the LK CMM can be created from the same CAD model using LK CAMIO software in advance of the first part being produced.

All inspection routines for both LK CMMs are now prepared this way in CAMIO, which performs not just programming but also analysis of the captured data and automatic reporting of the results. The measurement program enables the first-off part to be checked immediately on its first visit to the AlteraS 15.10.8; and while programming is quicker than before, the biggest plus point is that it is completed off-line so the CMM is not occupied, allowing inspection of components to continue uninterrupted.

Together with the benefit of multi-sensor capability, permitting the use of a Renishaw SP25 scanning probe or a Nikon LC15Dx laser scanning head instead of a touch-trigger probe, measuring throughput has been raised dramatically.

Mr Blood said: “Our new measuring processes can be used by personnel with a wide range of experience levels. The high degree of automation plus the ability to increase speed by scanning as well as touch-probing have helped us save time and remove inspection bottlenecks.

“Automation and the de-skilling of operations have also allowed us to enhance inspection efficiency without adding to our headcount. Added to this, every day there is a further economic advantage through the ability to run the CMMs unattended for up to 2hr at the end of each day shift thanks to our strategy of batch loading.”

Mr Parr added: “The parts we produce typically range in size from about 5mmLsup>2 up to 115mm in diameter x 250mm long. At one end of the scale they are milled, turned, ground, spark eroded and diamond lapped from free cutting brass, aluminium and stainless steel, but very often they are machined from the toughest of alloys — including Inconel 718, Invar or Hastelloy. Consistently high precision is the watchword here, with machined tolerances normally of the order of ±25µm but down to ±3µm if necessary.

“Nearly all components are inspected on our LK CMMs. There is enough spare capacity now to provide our customers with an additional service whereby, if required, some components that we do not manufacture for them are also inspected here and certified by us.”