Telford-based

Vargus Tooling (UK) Ltd, a developer, manufacturer and supplier of precision threading, grooving, turning and hand-deburring tools, has launched its new series of MACH Supersonic threading products.

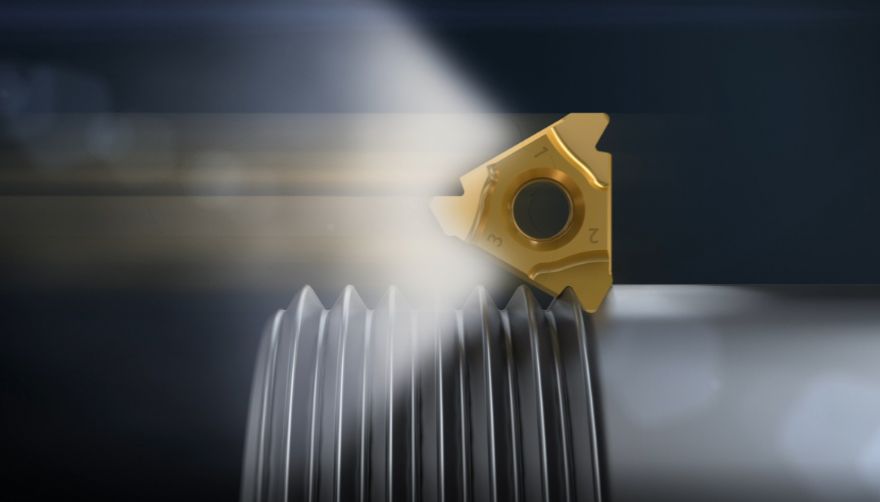

The patent-pending turning range has been introduced with a comprehensive range of MACH TT external inserts and corresponding MACH TT toolholders. The MACH TT external turning inserts are available with both a 55 and 60deg partial profile, ISO metric, American UN, Whitworth for BSW and BSP, BSPT, NPT, NPTF, Round and Trapez, UNJ, MJ, API Round and Metric Buttress.

This range of inserts that caters for the entire threading spectrum is capable of producing threads at speed due to several unique innovations. Each of the respective thread geometries incorporates an improved rake with a reinforced geometry that creates a strong insert design with a high resistance that permits cutting at higher speeds and reduces the number of passes required.

Adding to this geometry is Vargus’ new VK8 insert grades that combine an AlTiN and TiN PVD coating to give exceptional durability and performance on a range of materials from steel and stainless steel, cast iron and non-ferrous materials through to heat-resistant alloys and hardened steels.

The advanced surface treatment and improved profile design reinforce the strength of the cutting edge while providing a smooth surface finish and superior thread profile. This abundance of innovations reduces the number of passes required to dramatically decrease machining times and extend tool life whilst delivering unsurpassed thread quality.

Every thread designation is available with a vast array of dimensions and thread pitches to meet all of the threading demands of the industry. Working in complete synergy with the indexable triangular inserts is the respective toolholder with the Vargus dovetailed clamping system that is extremely rigid for high load machining.

The toolholders are available without or with through coolant facility that improves chip breaking and prolongs the life of the tool by delivering high-pressure coolant directly to the cutting edge with both a top and bottom coolant outlet channel.

The tool shanks are available with a 12 or 16mm width and depth for application on Swiss-type sliding head turning centres with 20, 25 and 32mm toolholders also available for application on a complete range of turning centres. Additionally, the toolholders are available in lengths from 84.5 to 170mm to suit specific machine tools.

Alongside the thread turning range of MACH products from Vargus is the new MACH TM thread milling range. Like the thread turning range, the MACH TM thread milling line is available in a complete range of thread geometries to cater for all requirements. The solid carbide high-performance treadmills incorporate an improved cutting-edge design with a reinforced geometry to allow cutting under high loads with maximum efficiency.

Complementing this design is a large core diameter that increases the stability and strength of the MACH TM series to enable higher speed and feed rates. It features a fourth flute that improves cutting performance and evacuates the swarf at speed. Assisting this tool design in removing chips from the cutting area is a through-coolant facility that flushes the swarf from the cutting edge.

For prolonged machining performance, Vargus has introduced its innovative new VH4 high wear resistance TiCN PVD coating technology to its new MACH TM series. This advanced surface treatment enables the new thread mills to improve surface finishes while prolonging tool life by reinforcing the cutting edge. Creating further stability and rigidity for the cutting edge, Vargus has also optimised the flute length.

The helical flute tools are available in a complete range of thread sizes and pitches to suit the end user’s requirements. For example, the ISO Metric thread mills are available from M3 to M20 with both coarse and fine pitch options with tool diameters from 3 to 16mm and lengths from 28 to 102mm with four or five flutes depending upon the selected tool diameter.

This wide range of sizes is also available in the NPT, BSP and American UN designations with thread mill sizes ranging from

1/8 to

2in depending upon the specified thread geometry.

Like the MACH TT thread turning series, the MACH TM line is a high-performance range that is capable of cutting materials from steel and stainless through to cast-iron nonferrous materials and heat resistant alloys.