The new Bumotec 191neo seven-axis mill-turn centre now available from

Starrag UK offers potential customers, especially in the medical device, luxury goods and micromechanics sectors money — and time-saving benefits for unrivalled low-cost machining of complex, higher-value parts.

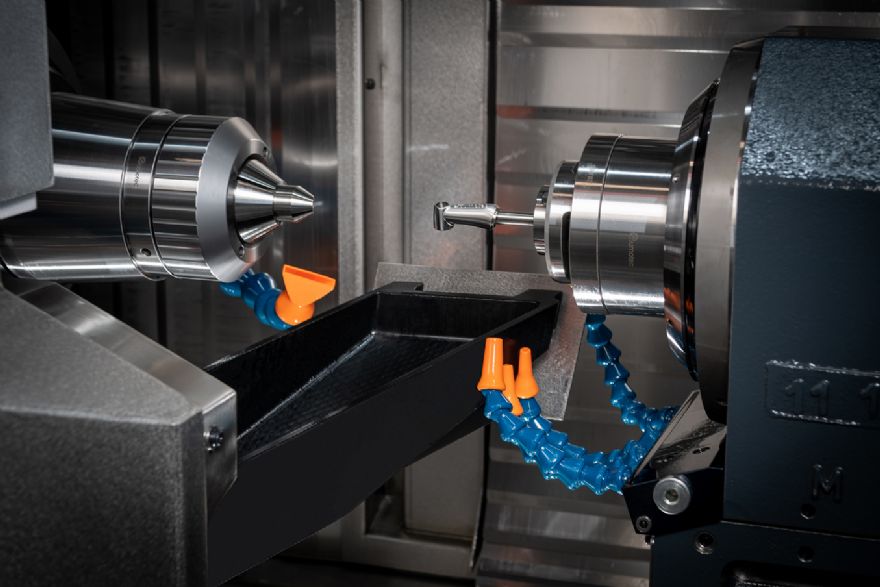

Evolved from Starrag‘s Bumotec flagship 191 machining centre renowned for its reliability and high performance, the 191neo takes the possible production benefits available from one-hit machining to new heights thanks to: lower than ever machine cost, courtesy lean manufacturing techniques; 15% reduction in tool change time; 12% faster back-working movement; and a higher torque (175Nm) milling spindle.

The result is a machine that can be offered at a significantly cost-competitive price to enable users to achieve lower than ever piece part costs.

With ergonomic design that includes large window areas so operators can clearly see all working zones, as well as perfectly-positioned doors for excellent access, the machine can accommodate bar of 42, 50 and 65mm, and has 50m/min traverse rates for its X-, Y- and Z-axis travels of 410, 200 and 400mm, respectively.

Main spindle options extend up to 22kW with a torque rating of 175Nm, while the 15kW/36Nm sub-spindle operates at 6,000rev/min. Importantly, in addition to milling and turning routines, the 191neo can also be used for grinding, polishing, skiving, gear hobbing and diamond cutting with no set-up or fixture changes.

Available in four options — P model with vice, PRM with multi-purpose pick-up vice, R with back-working spindle and RP version with combined vice and back-working spindle — the 191neo is effectively available in 12 versions.

Like its predecessor, the machine is also extremely stable during production and with a 90-position tool magazine that operates in parallel with integrated tool breakage probing, plus a pallet system and being configured for a robotic, modular or custom-made automated cell, users have access to 24/7 production regimes. Other options include temperature-controlled, high pressure chip conveyor and bar loading.

Focused on ‘digital transformation’ to ensure compatibility with the latest production technologies and remote access management, the191neo has a touch display with user-friendly and intuitive interface that can easily and quickly be used to swipe between screens to, for instance, monitor the progress of current machining operations, configure programming or track production in real time.