Having identified a gap in the UK automotive market for a highly efficient sub-contractor that specialises in the production of premium-quality low-volume components, the founders of

Opus International Products Ltd established their business in 2013. In less than 10 years the company has grown rapidly and now has a customer base that includes manufacturers of premium vehicles, supercars and electric cars, and sees it working with OEMs, Tier One suppliers and manufacturers at all levels of the production chain.

Given the company’s relatively short production runs, to help reduce changeover times and to increase its machine tools’ levels of efficiency, Rob Coles, Opus International’s managing director, recently investigated work-holding systems that would improve the company’s machining productivity. He subsequently selected systems from Long Crendon-based

Lang Technik UK Ltd. Now in constant use, these systems have enabled Opus International’s machine tools to significantly increase its output.

Mr Coles said: “In addition to relatively small batch numbers, many of the components we produce

feature complex configurations with challenging dimensional tolerances. These factors create a range of manufacturing difficulties, not least the ability to achieve maximum machining efficiencies. By using our Lang Technik work-holding systems on our Haas machining centres we have achieved the incremental production increases we were aiming for.

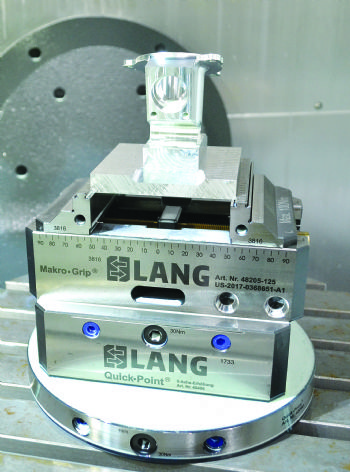

Now, before inserting a workpiece blank into one of our new Lang Makro-Grip vices, our staff use our Lang Technik stamping unit (pictured left) to make very accurate, minute indentations into the workpiece. Then, as the ‘male’ features on the jaws of our LANG vices exactly engage with the workpiece’s pre-stamped ‘dents’, we can achieve excellent holding power while only needing to apply minimal clamping forces.

“As a consequence, these vices can securely hold each workpiece with the application of minimum pressure, thereby allowing us to securely hold a range of materials — from the softest to the hardest — under all machining conditions without fear of deformation or other similar problems. In addition, as the Lang Technik stamping unit makes its indentations into only the last 3mm of workpieces, we make savings on material; and as all the indenting preparation work is carried-out before each workpiece is placed into the machine tool, the use of our new stamping unit and Makro-Grip vices has cut our machine downtimes.”

A different technologyLang Technik says it pre-stamping technology and Makro-Grip vices are “fundamentally different from the clamping methods of other work-holding manufacturers. The advantages gained from the Lang Technik system means that it has become the benchmark clamping method for secure five-axis machining.

“The toothed jaws of conventional vices must satisfy two distinct functions, in addition to indenting a workpiece’s material, they must also securely hold the workpiece. Conventional vices can only exert a maximum pressure of some 4-6 tonnes, therefore the effective penetration of conventional vice jaws into workpiece materials can be extremely difficult, especially when clamping harder materials.

“To ensure that the workpiece is penetrated correctly, a vice’s teeth must remain sharp to continue to be effective. However, as they are subjected to high levels of torque and wear, their clamping ability inevitably declines over time; and when using conventional vices during the machining of soft, distortion-prone materials, jaw teeth also tend to lose their holding power as they are inclined to work free of the workpiece under machining forces.

“The use of Lang Technik’s stamping technology overcomes these problems by applying up to 20 tonnes of pressure during pre-stamping to produce precise indentations in the workpiece; and because the teeth of the Makro-Grip vice engage perfectly with the pre-stamped indents, only low clamping pressure is required to hold a workpiece securely. In addition to holding the workpiece in the Makro Grip vice under the most severe machining conditions, the truncated pyramidal shapes of the pre-stamped indents prevent the vice’s teeth from impacting deeper into the workpiece by providing a definitive penetration limit.”

Also making a significant contribution to Opus International’s machining efficiencies is Lang Technik’s Quick-Point system, which acts as an interface between the machine tool’s table and its work-holding equipment.

Designed to reduce set-up times and to allow work to be quickly and accurately transferred from one machine to another with high levels of location repeatability, Quick-Point is available in a wide range of variants to suit most machine tools and applications. The high-precision exchange of clamping devices, fixtures and workpieces between machines using the system can be carried-out within seconds with location repeatability within 0.005mm.

Mr Coles added: “The help we received from Lang Technik UK before we placed an order enabled us to cover the maximum number of work-holding applications with a minimum of the company’s work-holding products. Such are the machining efficiencies we have gained through use of the company’s systems, as we continue to ramp-up our production levels we will be increasing our use of Lang Technik products.