Bath-based

RPI, a UK provider of rotary measurement and angular positioning devices, has expanded the company’s metrology product range with the launch of OctoScan. This is a ‘fast and highly accurate’ rotary axis designed to enhance the measurement capability of portable measurement arms by enabling objects that are larger than the standard reach of the portable arm ‘to be easily and accurately recorded’.

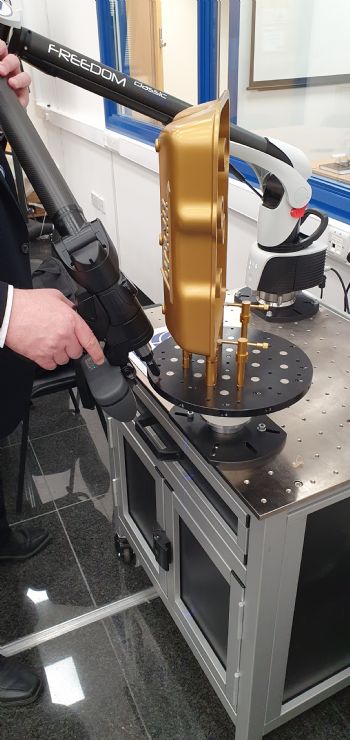

OctoScan is also ‘built with convenience in mind’, offering a ‘wireless capability and portability’ around a production line — and it can be integrated with any measurement arm or portable CMM. An LK Metrology Freedom Arm measuring system was recently demonstrated at

Control 2022 in Stuttgart integrated with an OctoScan via PolyWorks software.

Furthermore, the rotary axis has been designed so that parts can be fixed into place in many ways, with the unit’s built-in magnets and multiple threaded fixing holes allowing for an element of bespoke fixing.

RPI says that OctoScan can increase overall workplace productivity by up to 40%, while also significantly minimising human error and fatigue by eliminating the need for repeat measurements of certain parts that would typically stand outside the measurement range. The unit has a radial and axial run-out of 1µm and a ‘coning of axis’ of ±0.5arc sec.

Peter Marchbank, RPI’s managing director, said: “The launch of a new line of products is always an interesting time for both us and our customers, and with OctoScan I can already envision how it will influence workflows in many industries.

“One thing that users are going to notice almost immediately is the increased efficiency the unit brings to the workplace; and when considering the increased measurement volume and enhanced accuracy OctoScan offers, repeat measurements and human error will become less of a problem — and the unit can be moved around a production line to almost anywhere it is needed.”