Photos courtesy of Siemens Financial Services

Photos courtesy of Siemens Financial ServicesLike all industries, the machine tools sector has not escaped the impact of the Covid-19 pandemic. Reflecting on the last couple of years, Stefania Moruzzi, Siemens Financial Services UK business development manager, said: “On the one hand, the biggest consumer of machine tools, the automotive industry, has seen a significant drop in production while on the other, the sector has endured the resulting supply chain disruptions right across the manufacturing spectrum.”

Nonetheless, research estimates that the global machine tools sector will see nearly 4% growth over the period 2020-2024. This uptick can be seen in the context of a wider manufacturing trend linked to surviving the effects of the pandemic, that is the increased adoption of integrated digital solutions.

As manufacturers invest in agile technologies that help businesses swiftly respond to the demands of the time, this is expected to drive growth in the machine tools market.

Ms Moruzzi (pictured left) added: “After the lockdown period, and as businesses return to the new normal, automated equipment and technologies can help machine tools manufacturers to avoid further disruptions, keep pace with increased demand and support end-user customers.

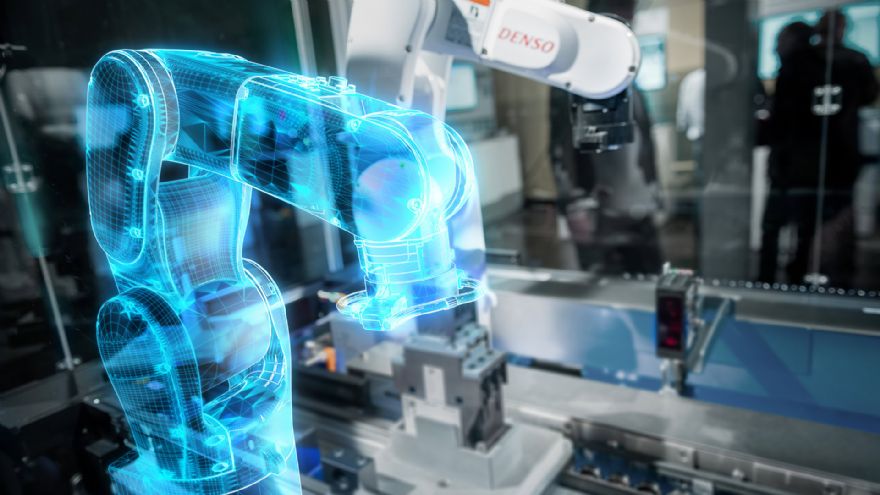

“Machine design and production is increasingly virtualised with‘digital twins’ becoming increasingly popular, making it easier, faster and less expensive to develop and test client machine and software configurations – often in digital collaboration with the client.

“This means faster time from specification to delivery for each build. When developing machine control applications, the virtual testing can eliminate four-fifths of the work previously needed. Supervisory Control and Data Acquisition (SCADA) functionality, made possible through digital sensors, is making it easier for machine manufacturers to collect and archive production data.’

The results are: advances in predictive analytics for maximum uptime; remote adjustment and optimisation; near-zero defect operating environments; and advanced remote metrology. Likewise, edge computing improvements are bringing computational power closer to the point of use to improve response times and save bandwidth. Embedded machine learning algorithms are helping machines to automatically adjust and refine their parameters to improve accuracy and efficiency.

Cautious manufacturers might be tempted to wait and see how much competitive advantage early adopters gain from digitalisation.

Smart finance techniquesMs Moruzzi explained: “Failing to invest early, however, may well be a strategic mistake. A previous global study from

Siemens Financial Services has shown that the window of opportunity to gain competitive advantage through digitalisation investments is narrowing, with a ‘tipping point’ of 5-7 years, after which manufacturers will be playing catch-up.

“Challenges to implementing digital transformation tend to pivot around the issue of finance – particularly during this time of economic turbulence. These barriers, however, can be overcome using smart finance techniques - known as ‘Finance 4.0’ - which cover the full range of requirements, from the acquisition of a single digitalised piece of equipment, to financing a whole new factory.

“Smart financing techniques help manufacturers to address the need to invest, to harness sustainable third-party capital to reduce the burden on corporate lines of credit, as well as to deploy cashflow management techniques that help maximise available working capital. All of these are playing a crucial role in helping manufacturers deal with the current period of volatile markets and economics.”

Smart finance solutions tend to be offered by specialist financiers, where the funder understands the technology, the markets, the applications and the operating pressures and where financing is an integrated part of the discussions with technology vendors. Using this knowledge, they create and align financing structures which are focused on achieving recognisable and clearly identified desired business outcomes for the manufacturer, through access to the right technology, services and advisory.

Ms Moruzzi continued: “Currently, one of the greatest advantages of such an approach is the ability to flex and adapt rapidly to market challenges. More broadly, these financing techniques align payments to the expected rate of return-on-investment delivered through new technologies and equipment.

“Many machine tools manufacturers are under pressure not simply to offer high performance digitalised technology but also provide a value proposition to their clients that makes it easy and commercially sustainable for them to upgrade their equipment and systems. Having used asset finance to secure their own equipment, they can personally promote integrated finance to their customers.

“Such an offering can streamline business interactions and act as an enabler of sales activity. Moreover, having finance as an embedded part of their solution allows equipment manufacturers to capture more sales as the process is simple and easy to conclude, while their own personal experience with the process speaks to clients.”

She concluded: “With digitalised equipment and technology seen as vital for manufacturing businesses to thrive in the new normal, machine tools manufacturers are under pressure to invest and help end customers do the same. As well as turning to specialist finance as a means of accessing investment, with integrated finance machine tools manufacturers can offer customers a sustainable pathway to digital transformation.”