Evotech Performance

Evotech Performance, a spin-off from Alford-based

Drury Precision Engineering, which specialises in the motorcycle aftermarket, had been using its CAM system for some 15 years, but needed to update this to optimise the capabilities of its five-axis machining investment. The company selected HyperMill CAM software from Bicester-based

Open Mind Technologies UK Ltd.

Discussing his background with the company, Nick Cooper — the production manager and a director of the Lincolnshire-based company that he has been with since 1999 — said: “Rob Drury, the company’s original director, accepted me on work experience. In 2005, Evotech Performance was established and has since secured a significant position in the global motorcycle aftermarket, subsequently evolving from simple fabrication to complex five-axis machining, to meet the growing sophistication needed by modern motorcycle manufacturers and enthusiasts.

“We started by making tail tidies because one of our directors wanted one for his own motorcycle, soon adding radiator guards and crash protection parts; and having taken on more designers we are now expanding our portfolio of parts. However, to stay ahead of competitors who were attempting to copy our designs we needed to increase their complexity and make them look even better. This need led to us investing in a DMG Mori DMP 70 five-axis simultaneous machine, which in turn required us to use advanced CAM software capable of fully exploiting its capabilities — hence our purchase of HyperMill, to not only make parts better but also quicker.

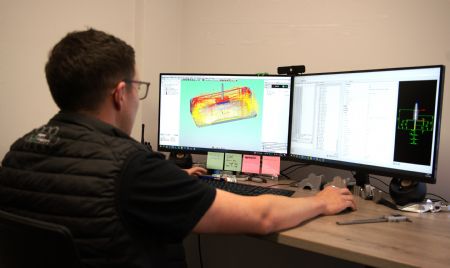

Advanced fixturing solutionsMr Cooper points out that unlike ‘traditional systems’ that need a separate CAD suite, HyperMill includes HyperCAD-S. This enables direct geometry modification within the CAM environment, thereby streamlining programming. “Furthermore, HyperMill has actually brought a new element that we hadn’t anticipated, as with the simple-to-use CAD suite built into HyperMill we can even design our own fixturing — a capability that has moved us on another level from where we thought we would actually be, as we can now develop advanced fixturing solutions that maximise our machine utilisation.

“Indeed, this capability has proved crucial for our large pallet machine operations, where efficient workholding directly impacts productivity and part accuracy, as we can design design our own fixturing for our large pallet machine, and then machine multiple parts with the fixturing — and we can validate part geometry and fixturing simultaneously.”

Mr Cooper said that while one of the largest challenges for precision manufacturing firms is a skills shortage, and that traditional five-axis programming requires considerable expertise, the user-friendly interface and automation offered by HyperMill Evotech overcome this. “The HyperCAD-S and HyperMILL training has worked so well that we subsequently trained two more operators from the shopfloor, and straight away, they were making five-axis simultaneous parts.

“Furthermore, HyperMILL provides predefined workflow steps that automatically identify potential programming errors, and this capability plays a key role in enabling less experienced programmers to achieve professional results, while the ability to verify programs before production is crucial for prototype development and minimising learning time.

“We have also found that HyperMill’s simulation is really effective and gives our operators complete confidence to put the program on the machine and start cutting material, knowing the post they have put out is going to be correct — particularly as HyperMill’s ‘Virtual Machining’ technology simulates the actual generated NC code rather than just the CAM toolpaths. This ensures unprecedented accuracy in virtual validation, as it accounts for machine kinematics, post-processor effects, and actual cutting conditions.”

More design freedomMr Cooper went on to say that HyperMill has delivered ‘quantifiable benefits’ across Evotech’s operations. “This software has enabled us to reduce our material stock as well as reduce our cycle times. We also have more design freedom, which means we can machine parts more easily — while making more products, and faster, than we have ever done before.

“Indeed, the enhanced capabilities enabled by HyperMill have positioned our company for continued market expansion with the ability to manufacture more complex parts with shorter development cycles, respond rapidly to market opportunities, and stay ahead of competitors. We have a continual flow of new and technically advanced products coming out all the time, and getting these onto the machine and cutting them very quickly is obviously a huge benefit to us.

“Furthermore, the confidence we have gained from mastering HyperMill’s capabilities has enabled us to commit to further expansion, adding more machine tools knowing we can get programs straight onto them. Indeed, HyperMill’s scalability and comprehensive post-processor support enables seamless integration with a diversity of machine tools; and the ability this gives to standardise on a single CAM platform across multiple machines simplifies training, reduces programming complexity, and ensures consistent quality standards. That said, the decision to move from the CAM supplier we had used for 15 years didn’t come lightly, and we imagined it would be a daunting task. However, the transition proved smoother than anticipated.”

Mr Cooper concluded: “The integration of design, programming, and manufacturing within a single software environment has enabled us to compress development cycles, improve part complexity, and maintain the quality standards essential for success in a competitive environment.”