Formed in 1969, HepcoMotion is the largest manufacturer of linear motion products in the UK; moreover, 75% of the company’s production is exported.

Giles Forster, who is chairman of the family-owned business, says: “We have to invest to stay ahead of the game. In the last three years, we have invested over £3 million in plant and equipment to maintain our leading position, and we are planning on doubling the size of the business over the next 10 years.”

The cutting-tool specialist Guhring Ltd, Birmingham (

www.guhring.co.uk), is one of the companies that has been helping HepcoMotion to increase its productivity and reduce costs.

The latter first used Guhring cutting tools some five years ago, and the successful implementation of Guhring drills, milling and threading products resulted in the Tiverton-based company holding a consignment stock of Guhring tooling.

Martin Shapland, CNC process engineer at HepcoMotion says: “We work closely with a Guhring technical sales engineer, who visits regularly to keep us abreast of all the latest technology and tooling developments.

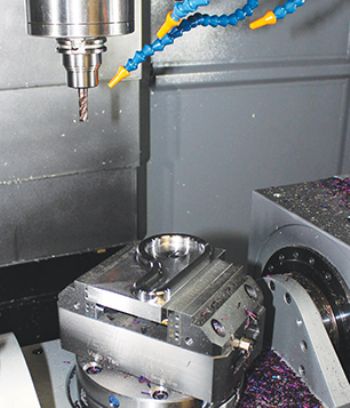

"We use a lot of Guhring’s milling, drilling and tapping products, including 5 x D solid-carbide drills and Ratio RF milling cutters, which have an unequal helix that is designed to improve chip flow and surface finish — and minimise vibration — to extend tool life and consistency.”

That said, while these tools have been giving HepcoMotion significant benefits, the company has started using a new line of cutting tools — Guhring’s RF Diver milling line, which was launched at the end of 2014. These tools have been developed for use as genuine ‘all-rounders’ that can undertake tasks from rough machining to finish machining on a wide range of materials.

HepcoMotion’s Ian Goffey says: “I first saw the new Diver line being demonstrated in Germany and instantly thought it would be ideal for the type of work we undertake.

“It is an extremely versatile four-fluted cutter with a flute spacing that is unique to this tool. It rapidly removes swarf from the work area, while its end geometry allows the tool to plunge in at 90deg or even ramp into a workpiece at 45deg — and it can be used for high-speed machining.

These tools also feature Guhring’s Signum coating technology, which dissipates heat and helps evacuate swarf.

“Diameters for the new Diver line start at 5.7mm, which allows us to interpolate corner radii while maintaining a constant chip thickness. It also supports the quick and efficient machining of keyways.

“Tool deflection can prevent the precision machining of keyways, but with the Diver, we can rough and finish a keyway precisely. Moreover, the ability of the Diver to undertake a number of tasks can reduce tool inventory and tooling costs — and cut the amount of production time lost to tool change-overs.

“At HepcoMotion, we are implementing high-performance cutting strategies with the Diver, such as trochoidal step-over machining. We stock the entire line of these tools, which includes diameters from 6 to 20mm and 5.7 to 15.6mm for undersized machining applications. The beauty of this tool is that it is truly universal.”

At HepcoMotion, an 11.7mm-diameter Diver tool is used to machine profiles on tool steel parts on the company’s Hurco machining centres at a cutting speed of 5,442rev/min and a feed rate of 1,088mm/min, plus a 1 x D depth of cut.

Once the profile is machined, the same cutter undertakes trochoidal milling at a feed rate of 360m/min and a spindle speed of 9,745rev/min. Previously, these machining operations were taking 20min; with the new Diver, the time has been cut to just 5min.