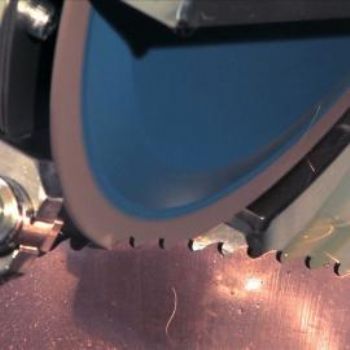

Stourbridge-based Dynashape, a leading saw blade servicing and manufacturing specialist, has invested £500,000 in the latest robotic CNC saw blade production technology.

The company, part of the Addison Group (

www.addisonsaws.co.uk), has added five new CNC machines to its machine tool inventory.

They will be housed in Dynashape’s new £300,000 service centre, which is scheduled to open later this year.

Operations Director, Chris Parkes said: “With more than 50 years of expertise, Dynashape is already recognised across the UK for its uncompromising saw blade servicing and refurbishing capabilities. This is because rather than ‘sharpen’ blunt blades our approach is to ‘re-manufacture’ them using advanced CNC machinery.

“As a result, our customers benefit from blades that, time after time, can be re-manufactured to perform as precisely and as efficiently as they did when new — for significantly less than the cost of purchasing new blades.”

Furthermore, Dynashape’s use of advanced CNC machining technologies and CAD packages means that it can improve the performance of new OEM-supplied products — and create bespoke cutting solutions and tooth profiles for superior cutting performance.

Mr Parkes added: “Accuracy, longevity and repeatability are essential to all our customers, regardless of the materials they are cutting.

“By investing in the latest four-, five- and six-axis CNC saw blade production machines from leading manufacturers such as Loroch, Vollmer and Walter, we offer our customers a one-stop solution for manufacturing and re-manufacturing TCT and SHSS saw blades, as well as PCD tooling.”