SmartCAMcnc (

www.SmartCAMcnc.com) has announced the release of SmartCAM v2016, which delivers a substantially updated knowledge-base machining (KBM) library, as well as improvements to the user interface and to the core milling functionality.

The improved KBM library supports the storing and re-use of tooling and operation settings, greatly increasing the efficiency with which new programs can be created using proven and repeatable processes. This ensures that consistent and accurate CNC methodologies are used throughout a manufacturing facility. Moreover, the associativity

feature of the KBM library allows jobs that use library definitions to be quickly updated to the most current definitions.

Doug Oliver, senior product manager at SmartCAMcnc, says: “SmartCAM has always allowed users to manage their tool and operation parameters in a variety of ways to fit their needs. With the improvements in the v2016 KBM library, that flexibility is still retained, but with the additional benefit of having all their manufacturing data stored and managed in a single repository.

"Additionally, the KBM library can be easily populated from existing jobs with just a few keystrokes. Data stored in the library can be given a group name and associated to materials and machines, allowing the data to be quickly filtered and recalled for re-use.”

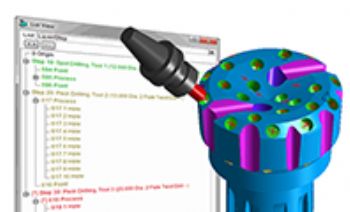

Several improvements to the user interface have been included to make SmartCAM even easier and more intuitive to learn and use. For example, List View, a key component of the interface, now displays model data in a “tree structure” that is expandable and collapsible. Moreover, CAD and CAM model elements can now be shown using this hierarchical list, which is convenient for viewing as much or as little detail of the model as needed.

A number of improvements have also been made to the rough-milling processes, as the Group Pocket process now supports separate pocket and island groups, including multi-level nested pockets and islands. Also added to Group Pocket are the Part Offset and Morph path-type options; these can be used to produce smoothed, continuously tangent tool-paths that are suitable for high-speed milling techniques.