Alphacam (

www.alphacam.com) 2017 R1 from Cheltenham-based Vero Software offers a number of enhancements designed to make it easier to use and to improve productivity, with the overall user experience augmented in a number of ways — including restyled dialogues to provide a more-intuitive layout, with images and tool tips included to help the user.

For example, the new 3-D machining dialogue provides the interface to multiple machining strategies in a consistent manner, with commands that include: along intersection; constant cusp; cylindrical parallel; cylindrical profiling; drive curves and Z contour roughing.

Meanwhile, the ‘work-plane properties’ option in the software’s project manager displays a window with a grid containing details of the work planes in the active drawing, such as the name and offset number, which can also be edited ‘in the grid’.

Additionally, it is now possible to rename the move clamp/fixture operation in the quick-edit window.

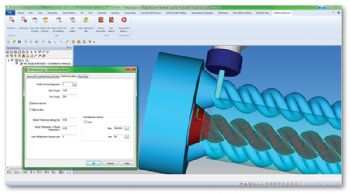

In the machining function, the cylindrical parallel strategy now gives the option of setting the width of cut as a distance; and when editing settings, the drawing area will update with a preview of the tool and holder, if applicable.

Furthermore, the machining area is indicated by a transparent shaded region around the part, which is updated automatically when settings are changed in the dialogue, allowing the user to visualise the effect that a change has on the operation.

Alphacam’s router function includes improved foul avoidance for sawing. Previously, when using a saw to cut parts, the risk of fouling other components was increased due to the size of the blade; 2017 R1 now checks for fouling against all geometries selected for the same operation, resulting in tool-paths being trimmed as necessary.

The simulator function sees X-Y configurations supported on both the head and table, with the transfer of five-axis tool-paths between Alphacam and the simulator optimised.

This means that complex operations containing tool-paths with thousands of individual elements take much less time to complete; and if program stops are included in the operation, they will now be recognised. Automation manager sees several new options.

These include feature extraction from faces (which enables the user to extract the solid-body outline of the part), plus the ability to copy and paste styles in the layer mapping set-up tree by right-clicking and selecting ‘copy’ or ‘paste’ from the menu (settings are retained when copying, which enhances efficiency).

In terms of general enhancements, work-volume support has been added to the parametric sketcher (useful with many post-processors that require the work-volume dimensions for the NC controller), and the area estimate routine has been improved to take account of drilled holes.