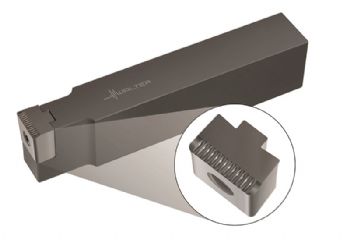

Following the introduction last year of an extended range of grooving blades and through-coolant tool-holders for its Cut-SX single-edged grooving system, Bromsgrove-based Walter GB Ltd (

www.walter-tools.com) has now made the system available with strengthened smaller-diameter shanks and in four variants.

G20242R/L grooving blades can now be supplied as left- and right-handed types, in both standard and ‘contra’ versions. The contra design is particularly useful when grooving in the immediate vicinity of the machine spindle, as it does not reduce the available clearance — a drawback associated with traditional tool shanks.

Meanwhile, G2012-P tool-holders with through-coolant are now also available in shank diameters of 12 and 16mm, complementing the existing 20 and 25mm sizes. The smaller versions will prove especially suitable on multi-spindle autos, for example.

In addition to these standard tools, there is a new clamping system that Walter says offers tool-life increases of up to 30% and greater process reliability when grooving and roughing slots in large components.

For example, when machining turbine shafts up to 3m in diameter x 15m long that require slots up to 100mm wide and deep, a common approach is to use a 19mm-wide grooving insert and progressively open up the slot in steps of 8-10mm.

However, with Walter’s clamping system, the slot width for each pass can be increased to 18mm, while improved chip-breaking enables swarf to be generated cleanly and reliably, says the company.