The 2017.2 version of HyperMill from Bicester-based Open Mind Technologies UK Ltd (

www.openmind-tech.com) provides a number of improved machining strategies, including 3D-optimised roughing and programming aids.

In addition, the company’s CAD software, HyperCAD-S, has been given a new module for the production of EDM electrodes.

The highlights of HyperMill 2017.2 include a new feature for the fast detection and programming of T-slots, which can now be produced with just a few clicks of a mouse.

Two types of feature recognition are available: ‘T-slots’ and ‘pockets with bottom and T-slots’.

Meanwhile, the 3-D machining method ‘rest material roughing’ is a particular feature in the latest HyperMill, which also offers a further in-feed strategy: the option ‘use infeed optimisation’ calculates the optimal in-feed value in connection with the additional chip thickness and depth values.

This allows the user to adjust the machining parameters to the condition of the tool. The key advantage is that tools with long cutting lengths can be used and controlled optimally.

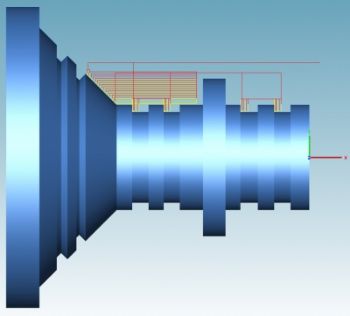

The electrode module in version 2017.2 of HyperCAD-S is an automated process ensuring the easy derivation of electrodes from the face of the component geometry that needs to be eroded.

Once the programmer has selected the workpiece faces, HyperCAD-S creates corresponding collision-free electrodes.

Further developments in HyperCAD-S include user-driven chain selection and the “positioning of components with the help of relationships”.

For example, elements such as clamping jaws can now be moved linearly or radially towards a central point between each other.