The ability of Mollart Engineering (

www.mollart.com) to respond to a major surge in automotive die-and-mould contracts — mostly from North America — has been enhanced by the use of specialist multi-axis deep-hole-drilling software that simplifies the programming of a variety of hole types and features.

This software allows Mollart’s Chessington-based operation to work directly from 3-D models, access the relevant data, and write programs more efficiently and with a high degree of accuracy; it also allows features — such as ports — to be more easily incorporated.

Producing these features can involve drilling, counterboring, reaming, thread milling and small-feed-hole drilling, as well as machining sealing faces and undertaking both milling and profiling.

These machining operations are carried out on Mollart’s own Matrix DHD, Prismabore PRB40 and Centeplex multi-axis dual-spindle special-purpose drilling and milling centres, as well as on a range of Mazak Integrex turn/mill centres.

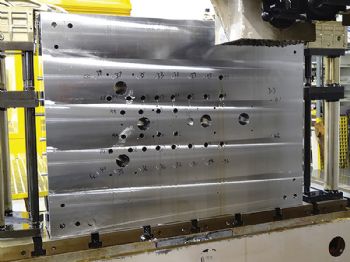

Operations director Mike Pragnell said: “We have enhanced our processing capability to include the one-off manufacture of moulds and dies — in steel and aluminium — that incorporate multiple cooling and venting holes with complex intersections.

“Our new software provides highly accurate program data to ensure that we maintain specific geometric relationships, and we are currently building our library of tooling and application data linked to material types.”

Mollart’s success in the North American automotive sector has been achieved through its ability to offer a complete machining package, backed up by a team with proven deep-hole-drilling expertise.

The company has been rough machining, semi-finish machining and drilling multiple holes in dies up to 2,500 x 2,500 x 300mm at the rate of 30 a month.