Chesterfield-based Dormer Pramet (

www.dormerpramet.com) has launched a range of high-feed cutters and inserts for machining a wide variety of materials.

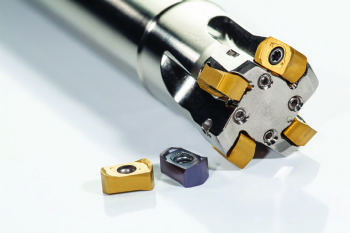

The Pramet SBN10 cutters, which are suitable for copy milling, ramping, helical interpolation, slotting and plunging, feature a pocket design that has been configured to carry inserts for shoulder and face milling, offering a complete package for mould-and-die applications in particular.

Suitable for both roughing and finishing tasks, the cutters are available in diameters from 16 to 42mm and in styles comprising end mills, modular mills and shell mills.

To go with the new SBN10 cutters, Dormer Pramet has introduced an assortment of BNGX10 inserts for high-feed roughing. These patented double-sided inserts offer four cutting edges and a design that makes them suitable for high-feed roughing, even with long overhangs.

Three geometries are available to cover most machined materials: M is for steel and cast iron; MM is for low-carbon steel, stainless steel and super alloys; and HM is suitable for hardened steel.

A further introduction is a range of Pramet ANHX10 inserts for finishing operations when performing shoulder milling and face milling. These single-sided inserts have two cutting edges and a positive geometry for use in long-overhang operations, helping to reduce vibrations and noise.

Both the BNGX10 and ANHX10 inserts offer a smooth cutting action, while a through-coolant design directs lubrication to near the cutting edge. This allows for high feed rates with axial depth of cut up to 1mm.

Furthermore, a high ramping angle improves chip control.